In industrial piping systems, failures rarely happen without warning — but they are often misunderstood until damage is already done. Among mechanical joints, pipe coupling threaded connections remain one of the most commonly used solutions worldwide due to their simplicity, cost efficiency, and ease of installation.

However, industry data consistently shows that a significant percentage of piping leaks and joint-related shutdowns originate from threaded connections. These failures are not random; they follow recognizable mechanical and environmental patterns.

Understanding these patterns is no longer optional. It is essential for engineers, procurement teams, and system designers who want to reduce downtime, avoid safety incidents, and extend system lifespan.

Key Insights You’ll Gain From This Guide

- The three most frequent failure mechanisms in threaded pipe couplings

- How mechanical stress and installation errors interact over time

- What industry data reveals about leakage and fatigue rates

- Conceptual comparisons between threaded, welded, and flanged joints

- Practical answers to search-driven, real-world user questions

Table of Contents

Introduction

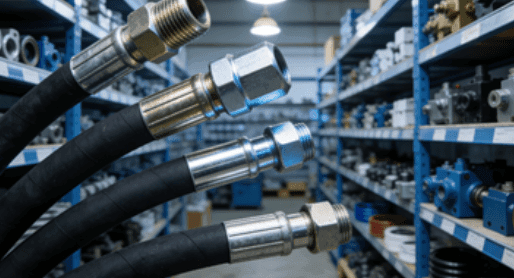

A pipe coupling threaded joint connects two pipes through interlocking male and female threads. While this design offers flexibility and quick assembly, it also introduces inherent stress concentration points.

According to widely cited industrial maintenance studies, threaded joints account for over 35% of low- to mid-pressure piping leaks in process systems. The root cause is rarely material alone — it is usually a combination of design choice, installation behavior, and operating conditions.

To understand why failures occur, we must examine the mechanics behind them.

Understanding How Pipe Coupling Threaded Connections Work

Thread Geometry and Load Transfer

Threaded couplings rely on helical grooves to transfer axial loads while maintaining alignment. Unlike welded joints, stress is distributed unevenly along the first few engaged threads.

Sealing Dependency

A pipe coupling threaded connection typically requires additional sealing media. The threads themselves are not designed to be perfectly leak-tight under pressure.

Sensitivity to Human Factors

Installation torque, alignment accuracy, and sealant choice heavily influence joint performance — more so than in permanent joining methods.

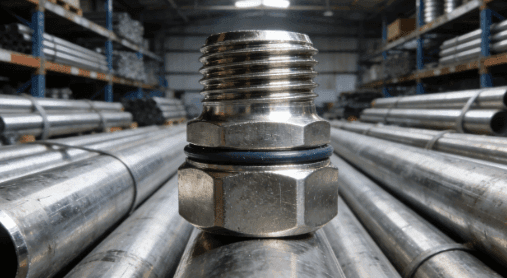

Failure #1: Thread Damage in Pipe Coupling Threaded Systems

Thread damage is the most visible and immediate form of failure.

What Is Thread Damage?

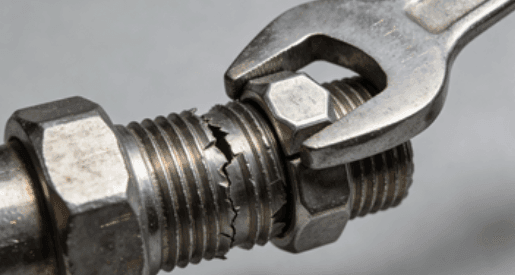

Thread damage refers to deformation, stripping, galling, or cracking of internal or external threads, reducing load-bearing capacity.

Why the First Threads Matter Most

Engineering analyses show that 60–70% of axial load in threaded joints is carried by the first three engaged threads. Damage here disproportionately weakens the entire connection.

Common Causes of Thread Damage

Over-Tightening Beyond Design Torque

Applying torque above recommended values increases hoop stress and leads to plastic deformation. This is especially common in carbon steel couplings installed without calibrated tools.

Cross-Threading During Assembly

Misalignment during initial engagement creates uneven contact, permanently damaging thread flanks.

Repeated Assembly and Disassembly

Each cycle causes micro-wear. Over time, tolerance loss accumulates, especially in softer materials.

Consequences of Thread Damage

Once threads deform, even proper sealant cannot compensate. The joint becomes vulnerable to vibration, pressure surges, and sudden disengagement.

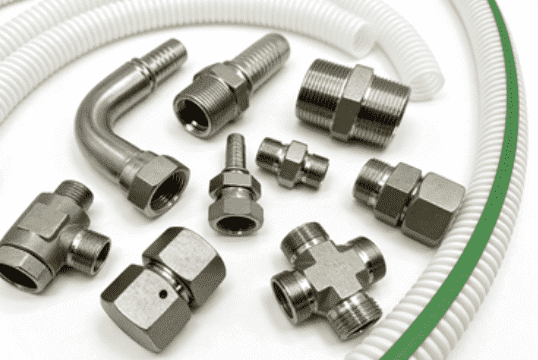

Failure #2: Leakage Due to Sealing Breakdown

Leakage is the most reported operational issue in pipe coupling threaded systems.

Why Threads Alone Cannot Seal

Threaded connections are designed for mechanical engagement, not fluid-tight sealing. Micro-gaps remain between mating surfaces.

Typical Sealing Methods

- PTFE tape

- Anaerobic liquid sealants

- Thread compounds

Each method has temperature and pressure limitations.

Key Leakage Triggers

Improper Sealant Coverage

Insufficient coverage leaves voids, while excessive application prevents full thread engagement.

Thermal Cycling Effects

Temperature changes cause differential expansion. Over time, this relaxes preload and compromises sealing integrity.

Pressure Pulsation

Repeated pressure fluctuations gradually force fluid through micro-gaps, even in initially tight joints.

Why Small Leaks Escalate

Minor seepage accelerates corrosion, reduces frictional resistance, and increases loosening risk — creating a feedback loop of degradation.

Failure #3: Stress Cracking from Mechanical and Environmental Loads

Stress cracking is less visible but more dangerous.

What Is Stress Cracking?

It refers to micro-fractures that develop under combined tensile stress and environmental exposure.

Common Contributors

Vibration-Induced Fatigue

Threaded joints lack the continuous material structure of welds, making them more susceptible to cyclic loading.

Chemical or Moisture Exposure

Certain environments promote corrosion-assisted cracking, particularly at thread roots where stress concentrates.

Why Detection Is Difficult

Cracks often initiate internally and propagate silently until failure occurs, making preventive inspection critical.

Quantifying Failure Risk: Industry Perspective

Typical Operating Limits for Threaded Couplings

- Pressure: generally below 300–400 psi for standard applications

- Temperature: performance declines significantly above 200°C depending on material

- Vibration tolerance: limited without secondary locking mechanisms

Maintenance Statistics

Maintenance surveys indicate that systems using threaded joints require 20–30% more frequent inspections compared to welded systems in similar environments.

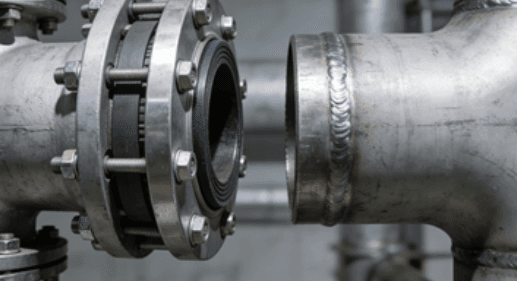

Threaded vs Welded vs Flanged: Conceptual Comparison

| Feature | Threaded Coupling | Welded Joint | Flanged Joint |

|---|---|---|---|

| Installation Speed | Fast | Slow | Medium |

| Pressure Capacity | Moderate | High | High |

| Vibration Resistance | Low | Very High | Medium |

| Reusability | High | None | Medium |

| Maintenance Access | Easy | Difficult | Easy |

This comparison highlights why pipe coupling threaded solutions remain relevant despite their limitations.

When Pipe Coupling Threaded Connections Make Sense

Ideal Application Scenarios

- Low to medium pressure systems

- Non-critical fluid transfer

- Temporary or modular installations

- Systems requiring frequent disassembly

When Alternatives Are Preferable

- High-pressure pipelines

- Continuous vibration environments

- Safety-critical fluid systems

Engineering Best Practices to Reduce Failures

Correct Torque Application

Using torque values aligned with thread size and material significantly reduces damage risk.

Material Compatibility

Matching coupling material with pipe material minimizes galvanic and thermal mismatch.

Alignment Control

Ensuring axial alignment before tightening prevents cross-threading and uneven load distribution.

Inspection and Early Warning Signs

Visual Indicators

- Thread deformation

- Sealant extrusion

- Corrosion at joint interface

Operational Symptoms

- Pressure drops

- Intermittent leakage

- Increased system noise

Early detection dramatically lowers repair costs.

Conclusion

A pipe coupling threaded connection remains a practical solution across many industries, but it is not a universal answer. Recognizing the three dominant failure modes — thread damage, sealing breakdown, and stress cracking — allows professionals to make informed design and maintenance decisions.

When applied correctly, threaded couplings deliver flexibility and efficiency. When misapplied, they become a predictable point of failure.

Engineering success lies not in avoiding threaded joints altogether, but in understanding exactly when and how to use them.

FAQ

What causes pipe coupling threaded joints to fail most often?

The most frequent causes include over-tightening, improper sealing practices, and vibration-induced fatigue.

Are pipe coupling threaded connections reliable long-term?

They are reliable when used within design limits and maintained properly, but they are not ideal for extreme conditions.

How often should threaded pipe couplings be inspected?

Inspection frequency depends on operating conditions, but many systems adopt quarterly or semi-annual checks.

Can sealants eliminate leakage completely?

Sealants reduce leakage risk but cannot compensate for damaged threads or improper joint design.