Table of Contents

Introduction

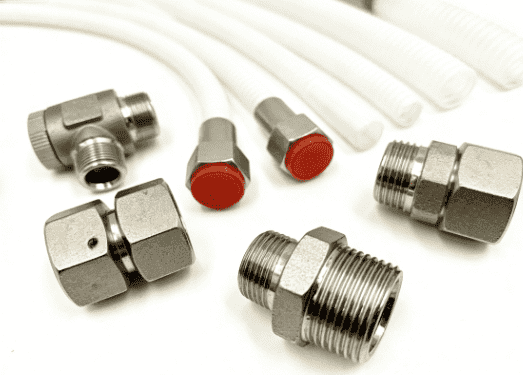

PTFE tube is a widely used component across chemical processing, 3D printing, automotive, medical, and food processing industries. Its excellent chemical resistance, low friction, and high-temperature tolerance make it indispensable. However, small mistakes in handling, installation, or selection can dramatically reduce performance. Mistakes can lead to leaks, pressure loss, material waste, and costly downtime.

Understanding the correct application of PTFE tubes ensures maximum system efficiency, durability, and safety. In this article, we explore the most common mistakes with PTFE tubes and provide actionable guidance for engineers, technicians, and DIY enthusiasts.

Mistake 1 – Using the Wrong Size PTFE Tube

The Problem

Selecting an incorrect inner diameter (ID) or outer diameter (OD) is a common but critical mistake. Too tight a fit stresses connectors and increases friction, while too loose a tube reduces flow efficiency and can compromise system pressure. Over time, mismatched tubing can also lead to wear, leaks, and potential damage to sensitive equipment.

Real-World Examples

In a German chemical plant, a batch of PTFE tubes with slightly larger inner diameters caused a 15% decrease in flow efficiency in solvent delivery lines. Similarly, in 3D printing applications, oversized tubes led to filament slipping inside hotend channels, resulting in frequent misprints and downtime for maintenance. In medical laboratories, incorrect tube sizes led to micro-leakage in automated fluid dispensing systems, affecting test accuracy.

Best Practices

- Measure ID and OD precisely using calipers or digital measuring tools.

- Consult manufacturer tolerance charts for recommended fits.

- For critical applications like medical or high-precision 3D printing, consider custom-cut PTFE tubes tailored to exact specifications.

- When replacing worn tubes, always check the system’s connector compatibility before installation.

Expert Advice

“Precision in tubing size is as critical as selecting the right adhesive or sealant,” says Dr. Hans Muller, a chemical process engineer with 20 years of experience in industrial fluid systems. “Even a 0.2 mm deviation in inner diameter can reduce flow efficiency noticeably in high-pressure systems.”

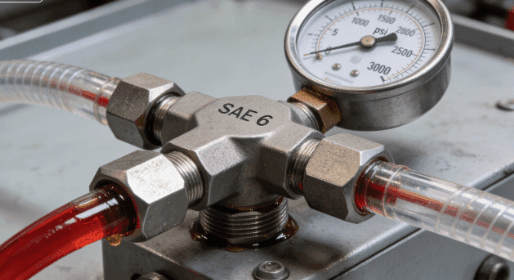

Mistake 2 – Ignoring Temperature Limits

The Problem

Although PTFE can handle a wide temperature range from -200°C to 260°C, exceeding these limits can lead to softening, deformation, or brittleness. Operating outside the recommended range reduces tube durability, alters flow characteristics, and may lead to system failure. High temperatures can accelerate creep in PTFE tubes, while extremely low temperatures can make them brittle.

Real-World Examples

- In high-temperature chemical reactors, PTFE tubes exposed to 300°C deformed and caused minor leaks in solvent lines.

- In cryogenic applications below -180°C, micro-cracks formed in PTFE tubing used for liquid nitrogen transfer.

- Automotive fuel systems using PTFE tubes near engine exhaust manifolds showed signs of softening and elongation, leading to repeated maintenance issues.

Best Practices

- Always cross-check operating temperature specifications from the tube manufacturer.

- For high-temperature applications, use reinforced PTFE tubes with fiberglass braid or stainless-steel outer layers.

- For cryogenic or low-temperature applications, consider specialty PTFE variants designed to maintain flexibility at ultra-low temperatures.

- Monitor system temperatures during operation and schedule inspections if the tubing is near its thermal limit.

Expert Advice

John Li, a materials scientist specializing in polymer tubing, emphasizes, “PTFE has an impressive thermal range, but engineers often overlook cumulative effects of temperature cycles. Repeated heating and cooling can degrade the tube faster than a single extreme exposure.”

Mistake 3 – Poor Handling and Installation

The Problem

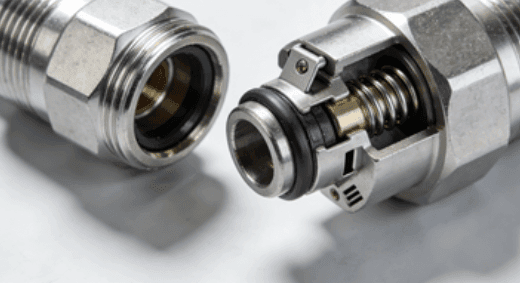

PTFE tubes are susceptible to damage from sharp bends, kinks, and abrasive handling. Improper insertion, twisting, or over-tightening in connectors can produce micro-tears that are invisible but compromise performance. These tiny flaws can grow under pressure or thermal stress, leading to leaks, reduced flow efficiency, and shortened tube lifespan.

Installation Pitfalls

- 22% of minor leaks in industrial fluid systems stem from micro-tears created during installation rather than operational wear.

- Sharp bends can cause ovalization of the tube cross-section, reducing effective flow area by up to 10%.

- Pulling a PTFE tube over rough edges or tight corners can cause scratches that accelerate degradation.

Recommendations

- Maintain the recommended bending radius (generally 6–10 times the tube diameter for standard PTFE).

- Avoid dragging tubes across sharp edges; use smooth guides or protective sleeves.

- Utilize insertion tools to reduce stress when connecting to fittings.

- Conduct pressure or flow tests after installation to detect hidden leaks.

Expert Advice

“Installation is where most mistakes occur,” notes Emily Carter, a senior engineer at a chemical automation company. “Even the most chemically resistant tube will fail if handled roughly or bent excessively. Correct training and handling procedures are critical.”

Mistake 4 – Using Incompatible Chemicals

The Problem

PTFE exhibits excellent chemical resistance, but not all PTFE tubes are compatible with every chemical. Aggressive solvents, molten alkali metals, and concentrated acids can degrade standard PTFE over time. Chemical exposure can cause swelling, cracking, or delamination in reinforced tubes.

Real-World Failures

- A U.S. plastics facility exposed PTFE tubes to concentrated nitric acid; the tubes swelled and cracked, reducing their effective lifespan by 50%.

- Automotive hydraulic systems experienced micro-leaks when using fluids incompatible with standard PTFE.

- Food processing lines using specialty cleaning chemicals found accelerated aging in PTFE tubing that was not rated for frequent chemical washdowns.

Expert Recommendations

- Consult chemical compatibility charts before use.

- For harsh or specialized chemicals, select reinforced PTFE tubes or chemically rated variants.

- Conduct laboratory tests for critical applications to ensure long-term stability.

- Replace tubing proactively in high-risk chemical lines to prevent downtime and contamination.

Mistake 5 – Neglecting Maintenance and Inspection

The Problem

Even PTFE tubes require periodic maintenance. Dust, debris, and micro-cracks accumulate over time, reducing flow efficiency and risking system failure. Neglecting inspections can lead to unexpected downtime, increased repair costs, or safety hazards.

Field Observations

- In a European 3D printing workshop, 25% of PTFE tubes in filament feed systems showed wear affecting extrusion consistency.

- In a pharmaceutical lab, uninspected PTFE tubes caused minor leaks, triggering expensive contamination containment procedures.

- Industrial pneumatic systems noted reduced air pressure in old PTFE tubing due to accumulated micro-cracks.

Maintenance Best Practices

- Schedule routine visual inspections and replace tubes showing any signs of wear or deformation.

- Keep spare tubes for rapid replacement, reducing downtime.

- Clean PTFE tubes where appropriate; ensure chemical residues do not remain.

- Monitor operational parameters like pressure, flow rate, and temperature to detect early signs of degradation.

Expert Advice

“Maintenance and inspection are non-negotiable,” emphasizes Dr. Karen Wong, a polymer materials specialist. “Even the highest quality PTFE tubes fail prematurely if overlooked. Establish a routine inspection schedule based on usage and environmental conditions.”

Mid-Article Comparison Table

| Mistake | Common Impact | Example Application | Risk Level | Recommended Solution |

|---|---|---|---|---|

| Using the Wrong Size PTFE Tube | Leaks, pressure loss | Chemical processing, 3D printing | High | Measure and select correct ID/OD |

| Ignoring Temperature Limits | Softening, brittleness | Reactors, cryogenic systems | Medium-High | Use temperature-rated tubes |

| Poor Handling and Installation | Kinks, micro-tears | Fluid transport, pneumatic lines | High | Follow bending radius & proper installation tools |

| Using Incompatible Chemicals | Swelling, cracking | Acidic or strong solvent transport | Medium | Verify chemical compatibility charts |

| Neglecting Maintenance | Reduced flow, unexpected failure | Printing, lab equipment | Medium-High | Schedule inspections & timely replacement |

Advantages of Correct PTFE Tube Use

Optimal Flow Efficiency

Proper tube sizing, careful installation, and correct handling reduce friction and maintain consistent fluid or filament transport efficiency.

Enhanced Durability

Maintaining temperature limits and using compatible chemicals prevent cracking, deformation, and aging, extending tube service life.

Safety Compliance

Routine inspections and maintenance help prevent leaks, chemical spills, and system hazards, ensuring industrial safety.

Reduced Downtime

Preventing mistakes avoids unexpected shutdowns, keeping production lines operational and reducing repair costs.

Cost Efficiency

Correct selection and maintenance reduce material waste and downtime, delivering measurable ROI over time.

Versatility Across Industries

PTFE tubes perform effectively in laboratories, 3D printing, chemical processing, automotive fuel lines, and medical applications when used properly.

Conclusion

PTFE tube performance can be drastically affected by common mistakes. Avoiding errors in sizing, temperature handling, installation, chemical compatibility, and maintenance ensures efficiency, safety, and longevity. Applying these best practices maximizes system performance and cost savings.

FAQ

Q1: How do I determine the correct PTFE tube size?

Measure ID/OD precisely and consult manufacturer specs. Custom cuts may be needed for precision applications.

Q2: Can PTFE tubes handle liquids above 260°C?

Standard PTFE should not exceed 260°C. High-temperature or reinforced variants are required.

Q3: How often should PTFE tubes be inspected?

Schedule regular inspections based on usage and environment. Replace any tube with cracks or wear.

Q4: Are PTFE tubes compatible with all chemicals?

No. Always check chemical compatibility charts. Use reinforced or specialty tubes for harsh chemicals.

Q5: How should PTFE tubes be installed?

Avoid sharp bends, use proper connectors and tools, and verify flow integrity after installation.