Table of Contents

Introduction

PTFE tubing is widely used in chemical processing, laboratory setups, medical equipment, and industrial applications due to its chemical resistance, high temperature tolerance, and non-stick properties. Despite its many advantages, PTFE tubing is not immune to operational challenges. Improper handling, environmental factors, or installation errors can lead to leaks, blockages, or premature wear, affecting both system efficiency and safety.

In this article, we explore six common PTFE tubing problems and provide effective solutions that help operators, engineers, and maintenance teams maintain optimal performance, prevent downtime, and extend the lifespan of tubing in various applications.

Problem 1: Leaks and Seal Failures in PTFE Tubing

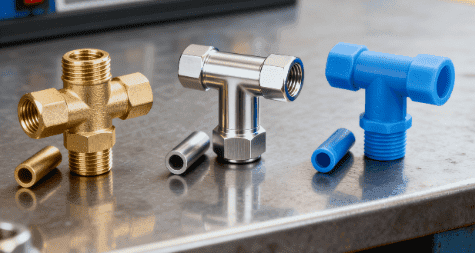

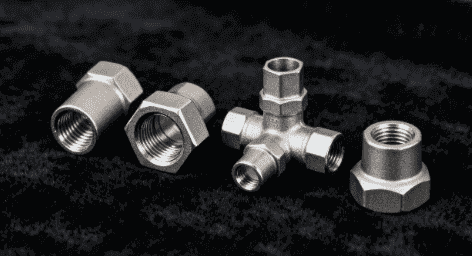

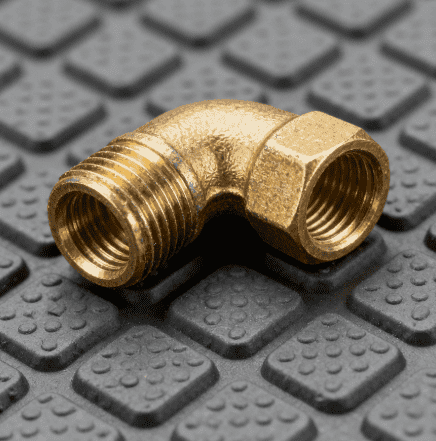

Leaks are one of the most frequent issues when using PTFE tubing, particularly in high-pressure systems. The flexible nature of the tubing and its smooth inner surface can sometimes make achieving a secure seal difficult. Common causes of leaks include improper fittings, over-tightening, or material fatigue after prolonged use.

Effective solutions involve selecting compatible fittings designed for PTFE tubing, avoiding excessive torque when securing connections, and periodically inspecting seals for signs of wear. Using reinforced PTFE tubing in high-pressure applications can also prevent burst or leakage incidents. Proper installation techniques and training staff on the nuances of PTFE fittings significantly reduce the likelihood of leaks.

Problem 2: Kinking and Tubing Deformation

PTFE tubing, while flexible, can be prone to kinking or bending when handled improperly. Kinks restrict fluid flow, increase backpressure, and can even compromise the integrity of the tubing over time.

To address this issue, operators should use tubing support systems, such as clamps or guides, to maintain gentle curves and prevent sharp bends. Choosing the appropriate wall thickness and tubing diameter for the application ensures sufficient rigidity without sacrificing flexibility. Additionally, heat-forming techniques can pre-shape tubing into desired paths, reducing the risk of accidental kinks during installation or operation.

Problem 3: Blockages and Contamination

In applications involving reactive chemicals, particulate matter, or viscous fluids, PTFE tubing can sometimes develop blockages. These blockages not only impede fluid flow but also increase operational pressure and risk damage to connected equipment.

Preventing contamination begins with thorough flushing of the tubing before use, using filters or inline strainers to capture particles, and regularly inspecting tubing for residue build-up. In systems with multiple bends or long lengths of tubing, automated cleaning cycles or periodic chemical rinsing may be necessary to maintain clear pathways. Choosing tubing with smooth inner surfaces, such as high-purity PTFE, further minimizes material adherence and reduces blockages.

Problem 4: Temperature and Pressure Limitations

PTFE tubing has excellent temperature and chemical resistance, but exceeding these limits can cause deformation, cracking, or collapse. Applications involving extremely high temperatures or vacuum pressures require careful consideration of tubing specifications.

Operators should verify the maximum pressure and temperature ratings of their PTFE tubing, and select reinforced or high-temperature variants when necessary. Installing tubing with gradual bends, avoiding tight coils, and using protective shielding can prevent damage due to thermal expansion or contraction. Monitoring system conditions with sensors helps ensure that operational parameters remain within safe limits, preserving the tubing’s performance and safety.

Problem 5: Chemical Compatibility Issues

While PTFE tubing is highly resistant to many chemicals, some aggressive substances or prolonged exposure to certain solvents can still degrade the material or reduce its mechanical strength. Understanding the chemical environment is crucial for ensuring reliable performance.

Selecting the right grade of PTFE tubing, consulting compatibility charts, and considering alternative materials for specific aggressive chemicals are effective strategies. In applications with continuous exposure to reactive substances, using protective coatings or secondary containment can further extend tubing lifespan. Regular inspections and replacing tubing before signs of degradation appear prevents system failures and costly downtime.

Problem 6: Difficulty in Installation and Handling

PTFE tubing’s flexibility and smooth surface, while advantageous, can make handling and installation challenging. Slipping, incorrect alignment with fittings, or improper routing can lead to operational inefficiencies or damage to the tubing.

Training staff on proper installation techniques, pre-cutting tubing to precise lengths, and using installation aids like push-to-connect fittings can simplify the process. Avoiding sharp bends and minimizing excessive handling also reduces the risk of internal stress or wall damage. With careful attention, operators can achieve a secure, leak-free, and efficient tubing installation.

Comparative Table: Common PTFE Tubing Problems and Solutions

| Problem | Typical Cause | Effective Solution | Benefit |

|---|---|---|---|

| Leaks and Seal Failures | Improper fittings, over-tightening | Use compatible fittings, check seals | Reduced downtime and safety risks |

| Kinking and Deformation | Sharp bends, unsupported tubing | Tubing guides, heat-forming techniques | Maintains flow efficiency |

| Blockages and Contamination | Particulate matter, viscous fluids | Inline filters, regular cleaning | Consistent flow, prevents pressure spikes |

| Temperature and Pressure Limits | Exceeding tubing specifications | Reinforced tubing, monitoring sensors | Prevents collapse or cracking |

| Chemical Compatibility Issues | Exposure to aggressive chemicals | Choose appropriate grade, protective coating | Prolongs tubing lifespan |

| Difficulty in Installation | Slipping, incorrect alignment | Staff training, installation aids | Faster, safer installation |

This table summarizes the main problems, causes, and practical solutions for PTFE tubing in industrial or laboratory settings, highlighting the importance of preventive strategies to maintain system reliability.

Additional Considerations for PTFE Tubing

Beyond addressing these six common problems, overall system efficiency also depends on environmental factors and operational practices. Avoiding excessive UV exposure, mechanical abrasion, or contact with sharp objects can preserve tubing integrity. Routine inspection schedules and proper labeling of tubing lines improve operational efficiency and safety. For complex systems, mapping out tubing routes and maintaining detailed documentation helps prevent errors during maintenance or modifications.

Combining technical knowledge, proper material selection, and proactive maintenance ensures that PTFE tubing continues to deliver reliable performance across diverse applications.

Conclusion

PTFE tubing provides unmatched chemical resistance, flexibility, and durability when used correctly. Understanding the common problems—leaks, kinks, blockages, temperature and pressure issues, chemical incompatibility, and installation difficulties—allows operators to implement effective solutions and maintain optimal system performance. By combining careful material selection, proper handling techniques, and regular monitoring, facilities can prevent downtime, improve safety, and extend tubing lifespan, ensuring reliable operation in a wide range of applications.

FAQ

Q1: How often should PTFE tubing be inspected for leaks?

Regular inspection is recommended at least once a month, or more frequently in high-pressure or critical chemical applications.

Q2: Can PTFE tubing handle all chemicals safely?

While highly resistant, certain aggressive solvents or prolonged exposure may degrade PTFE. Always consult chemical compatibility charts.

Q3: How can blockages in PTFE tubing be prevented?

Using inline filters, flushing tubing before use, and regular maintenance are key to preventing blockages.

Q4: What are the best practices for preventing kinks?

Support tubing with guides, use gentle bends, and consider heat-forming for pre-shaping complex routes.

Q5: Is reinforced PTFE tubing necessary for high-pressure systems?

Yes, reinforced or thicker-walled PTFE tubing is recommended for applications exceeding standard pressure limits to prevent leaks or bursts.