Table of Contents

Introduction

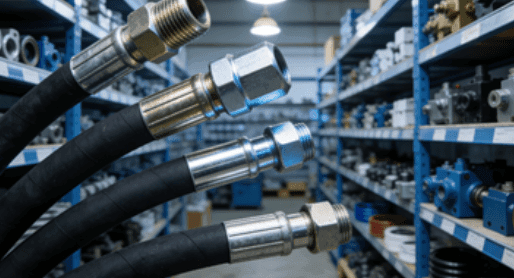

Hydraulic systems are the backbone of modern industrial machinery, construction equipment, agricultural machinery, and manufacturing plants. A critical component in these systems is the hydraulic hose connector, which ensures the safe and efficient transfer of hydraulic fluid under high pressure. Choosing the right hydraulic hose connector is essential not only for operational efficiency but also for safety, cost-effectiveness, and long-term durability.

Many operators face challenges when sourcing hydraulic hose connectors that combine affordability with high quality. Inadequate connectors can lead to leaks, system failure, reduced efficiency, and costly downtime. Therefore, understanding the features, materials, types, and best practices for selecting hydraulic hose connectors is crucial for technicians, engineers, and machinery operators alike.

This article will provide a comprehensive guide on seven affordable hydraulic hose connectors that maintain excellent quality. We will explore their features, applications, maintenance tips, common issues, and expert recommendations to help you make informed decisions for your hydraulic systems.

Understanding Hydraulic Hose Connectors

What is a Hydraulic Hose Connector?

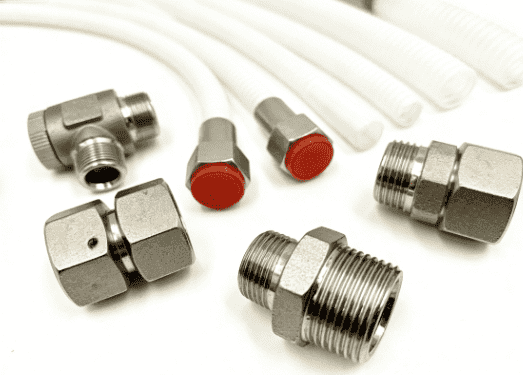

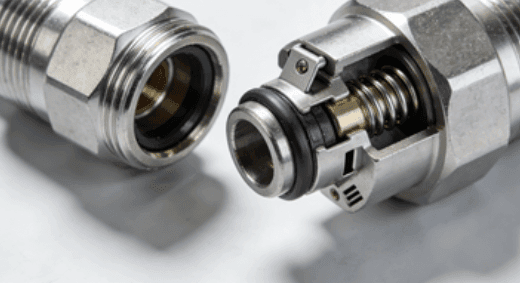

A hydraulic hose connector is a fitting that links hydraulic hoses to pumps, valves, cylinders, or other system components. These connectors are engineered to handle high pressure and prevent leakage. The design, material, and construction quality directly affect the performance, safety, and longevity of hydraulic systems.

Hydraulic hose connectors come in various types, including threaded, quick-connect, crimped, push-to-connect, and swivel designs. Each type serves specific applications, such as construction machinery, industrial presses, agricultural equipment, and mobile hydraulic systems.

Key Features to Look for in Hydraulic Hose Connectors

Selecting the right connector requires evaluating several critical factors:

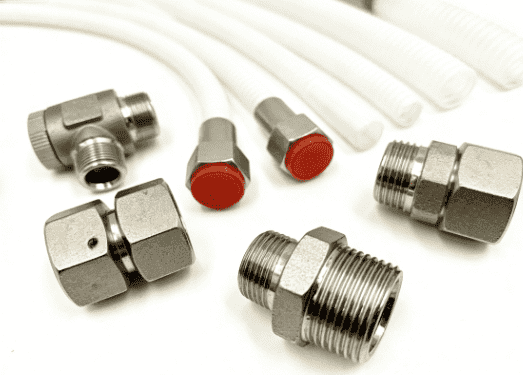

- Material Quality: Stainless steel, carbon steel, and brass are common choices. Stainless steel is corrosion-resistant, while carbon steel offers high strength and cost-effectiveness.

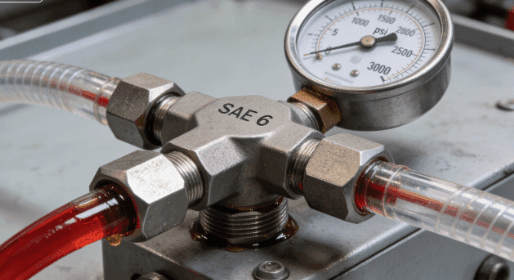

- Pressure Rating: Ensure the connector matches the maximum operating pressure of your system. Exceeding the rating may result in leaks or catastrophic failure.

- Sealing Mechanism: O-ring seals, bonded seals, or metal-to-metal seals are used depending on application needs. Proper sealing prevents fluid leakage and system contamination.

- Ease of Installation: Quick-connect or push-to-connect fittings save time during maintenance or hose replacement.

- Durability and Longevity: Consider connectors with protective coatings, high wear resistance, and thermal stability for long-term reliability.

Technicians recommend prioritizing quality materials and sealing mechanisms over just price. Even affordable connectors can provide excellent performance if properly selected.

7 Affordable Hydraulic Hose Connectors With Excellent Quality

When evaluating hydraulic hose connectors, both cost and quality are crucial. Here are seven options that strike the perfect balance between affordability and performance:

1. Crimped Hydraulic Hose Connectors

Crimped connectors are widely used due to their reliability and high-pressure handling. They are permanently secured to the hose using a crimping machine, ensuring leak-proof performance. Crimped connectors are ideal for industrial and mobile hydraulic systems that require consistent pressure ratings.

2. Quick-Connect Hydraulic Hose Connectors

Quick-connect connectors allow for rapid connection and disconnection without tools. They are particularly useful in applications where hoses need frequent replacement or repositioning. Many affordable quick-connect models now include stainless steel or high-quality brass for enhanced durability.

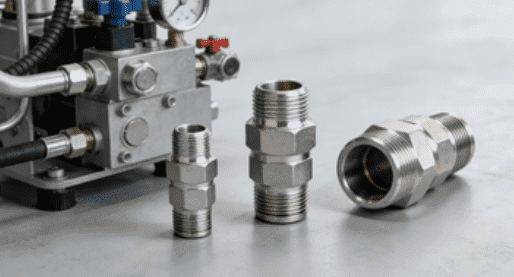

3. Threaded Hydraulic Hose Connectors

Threaded connectors provide a secure connection using a standard thread size. They are versatile and widely used in agricultural machinery, construction equipment, and industrial applications. Threaded connectors are cost-effective, easy to source, and reliable for moderate to high-pressure systems.

4. Push-to-Connect Hydraulic Hose Connectors

Push-to-connect fittings are designed for easy installation and maintenance. These connectors are ideal for low-pressure hydraulic circuits or pneumatic systems integrated with hydraulics. Many manufacturers produce affordable push-to-connect options without compromising durability.

5. Swivel Hydraulic Hose Connectors

Swivel connectors allow the hose to rotate freely, reducing stress and wear caused by twisting. They are particularly important for mobile machinery or systems with rotating components. Swivel connectors improve hose longevity and system reliability, even in harsh working environments.

6. Brass Hydraulic Hose Connectors

Brass connectors are corrosion-resistant, lightweight, and cost-effective. They are commonly used in agricultural or water-based hydraulic systems where stainless steel may not be necessary. High-quality brass connectors maintain excellent sealing and durability while remaining affordable.

7. Stainless Steel Hydraulic Hose Connectors

Stainless steel connectors offer exceptional resistance to corrosion, high pressure, and extreme temperatures. While they are slightly more expensive than brass or carbon steel, there are many affordable stainless steel options that provide excellent performance for industrial and marine applications.

Comparing Hydraulic Hose Connectors: Features and Applications

| Connector Type | Material | Pressure Rating | Ideal Use Case | Cost Range (USD) |

|---|---|---|---|---|

| Crimped | Carbon Steel/Stainless | Up to 5000 PSI | Industrial & Mobile Hydraulics | 5–15 |

| Quick-Connect | Brass/Stainless | Up to 3500 PSI | Frequent Hose Replacement | 8–20 |

| Threaded | Carbon Steel | Up to 4000 PSI | Agricultural & Construction | 4–12 |

| Push-to-Connect | Plastic/Brass | Up to 2000 PSI | Low-Pressure Systems | 3–10 |

| Swivel | Stainless/Brass | Up to 4500 PSI | Rotating Machinery | 10–25 |

| Brass | Brass | Up to 3000 PSI | Water & Agriculture | 3–12 |

| Stainless Steel | Stainless Steel | Up to 6000 PSI | Industrial & Marine | 12–30 |

This table highlights the versatility of hydraulic hose connectors and the balance between affordability and performance. Choosing the right connector ensures safe operations, long-lasting performance, and minimal maintenance costs.

Maintenance Tips for Hydraulic Hose Connectors

Regular Inspection

Periodic inspection of hydraulic hose connectors is crucial. Check for leaks, cracks, corrosion, or worn seals. Early detection prevents system failure and reduces downtime.

Proper Installation Practices

Ensuring connectors are correctly installed is vital. Over-tightening can damage threads or seals, while under-tightening may cause leaks. Always follow manufacturer torque recommendations.

Lubrication and Cleaning

Clean connectors regularly to remove debris, dirt, and hydraulic fluid residue. Lubricate threaded parts or swivel mechanisms to ensure smooth operation and prevent premature wear.

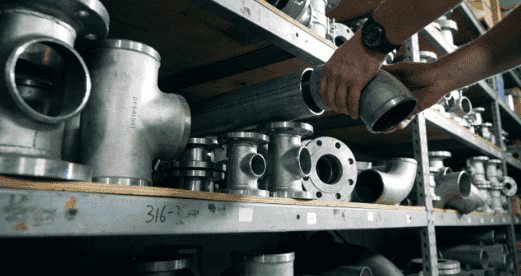

Storage Recommendations

Store spare connectors in a dry, clean environment. Avoid exposure to harsh chemicals or moisture, which can reduce lifespan and performance.

What Are Hydraulic Hose Connectors Used For?

Hydraulic hose connectors are critical in transferring hydraulic fluid safely between hoses, pumps, valves, and cylinders. They are used in:

- Construction equipment such as excavators, loaders, and cranes

- Industrial machinery like presses, injection molding machines, and lifts

- Agricultural machinery including tractors, sprayers, and harvesters

- Marine hydraulic systems and offshore equipment

- Mobile hydraulics in trucks, trailers, and forklifts

Proper selection and maintenance of hydraulic hose connectors ensure optimal hydraulic system performance and safety.

Common Issues and Troubleshooting

Leakage and Seal Failure

Leaks are the most common issue with hydraulic hose connectors. Inspect seals and O-rings for wear. Replace damaged components promptly.

Pressure Loss

Inadequate pressure can result from worn connectors or improper installation. Verify ratings and torque settings to maintain system efficiency.

Corrosion and Rust

Exposure to moisture or chemicals can corrode metal connectors. Use corrosion-resistant materials and protective coatings for long-term reliability.

Misalignment

Hoses must be correctly aligned to prevent stress and wear. Misalignment can lead to early failure or detachment.

Expert Recommendations for Selecting Affordable Hydraulic Hose Connectors

Experts emphasize balancing cost with quality. Key recommendations include:

- Opt for connectors made from high-quality brass or stainless steel for longevity

- Ensure pressure rating meets or exceeds system requirements

- Use proper sealing mechanisms, especially for high-pressure systems

- Consider ease of installation and maintenance to reduce downtime

- Replace worn connectors promptly to avoid costly failures

Industrial engineers often note that investing slightly more in durable connectors reduces long-term maintenance and replacement costs.

Conclusion

Choosing the right hydraulic hose connector is essential for system safety, performance, and cost-effectiveness. Affordable options exist that do not compromise on quality, provided you understand material properties, pressure ratings, installation practices, and maintenance needs. From crimped and threaded connectors to quick-connect and swivel types, each has its ideal application. By following best practices and expert recommendations, operators can ensure reliable, long-lasting hydraulic system performance while keeping costs manageable.

FAQ

Q1: Can I use a lower-rated hydraulic hose connector for high-pressure systems?

A: No, using a connector below the system’s rated pressure is dangerous and can result in leaks or catastrophic failure. Always match or exceed the system rating.

Q2: How often should hydraulic hose connectors be inspected?

A: Monthly inspections are recommended for high-usage systems. Visual checks for leaks, corrosion, or wear should be done more frequently if operating in harsh conditions.

Q3: Are quick-connect hydraulic hose connectors reliable for industrial use?

A: Yes, high-quality quick-connects made from brass or stainless steel are reliable and save time for systems that require frequent hose changes.

Q4: Can I reuse hydraulic hose connectors?

A: Some connectors, especially crimped types, are intended for single use. Threaded, swivel, and push-to-connect fittings can often be reused if inspected and maintained properly.

Q5: What materials are best for long-lasting hydraulic hose connectors?

A: Stainless steel and high-grade brass provide excellent corrosion resistance, durability, and reliability for both industrial and mobile hydraulic systems.