Table of Contents

Introduction

In the world of industrial materials, few options can match the performance, versatility, and durability of Polytetrafluoroethylene (PTFE) tube. This advanced polymer is favored across various industries for its superior properties, making it the material of choice in environments where durability, resistance to harsh conditions, and long-term performance are critical. With applications spanning from aerospace to pharmaceuticals, the PTFE tube is a key component in many industrial systems, where it outperforms other materials such as rubber, PVC, and metals.

In this blog, we’ll explore the top three reasons why Polytetrafluoroethylene tube outshines other materials in industries requiring high performance and long-term reliability. We’ll cover its heat resistance, chemical stability, and durability, providing you with a deeper understanding of why PTFE is a game-changer in harsh operational environments.

Why is Polytetrafluoroethylene Tube the Top Choice?

PTFE tubes stand out primarily because of their extraordinary resistance to heat, chemicals, and pressure. These tubes combine remarkable properties that give them an edge over conventional materials. By understanding these unique characteristics, you’ll see why they are used in critical applications where other materials simply can’t keep up. Let’s dive into each key reason why Polytetrafluoroethylene tube is an unparalleled material for many industries.

1. Exceptional High-Temperature Resistance

Polytetrafluoroethylene Tube’s Heat Durability

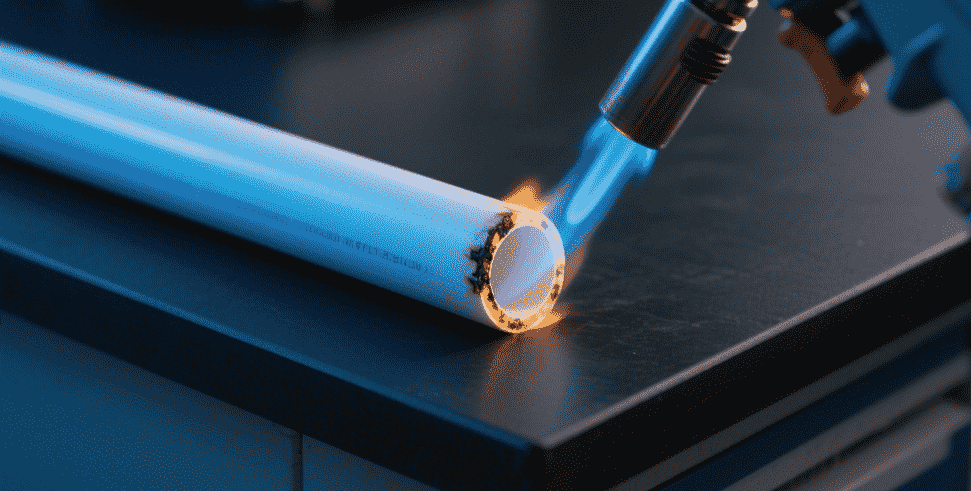

One of the most striking features of Polytetrafluoroethylene tube is its ability to maintain performance under extreme temperatures. Unlike materials such as rubber, PVC, or even metals, PTFE tubes can withstand very high temperatures without losing their structural integrity or functionality. PTFE tubes can endure temperatures as low as -60°C and as high as 250°C, making them ideal for use in industries that face high-heat conditions.

A key strength of PTFE is its ability to handle steam at 250°C, maintaining a surface temperature below 60°C. This ability to operate in extreme temperatures makes Polytetrafluoroethylene tube indispensable in high-heat applications like steam lines, boiler systems, and chemical reactors, where the environment is typically harsh and unforgiving.

Real-World Applications

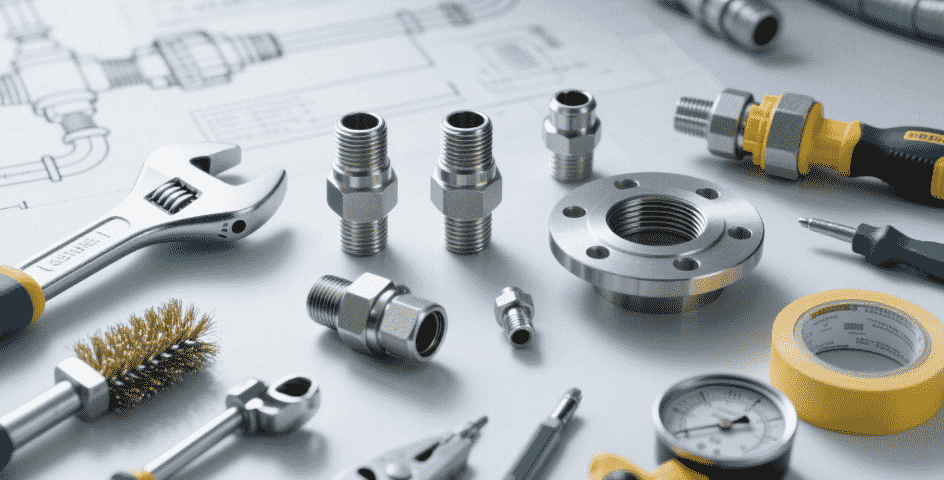

Industries that benefit from the high-temperature resistance of Polytetrafluoroethylene tube include:

- Aerospace: PTFE tubes help maintain systems that require high heat resistance, such as engine components and fuel lines.

- Automotive: They are used in coolant systems, hydraulic lines, and exhaust systems where elevated temperatures are common.

- Food and beverage: In food manufacturing, PTFE tubes are used for steam lines and sterilization equipment, where high-temperature resistance is essential for safety and quality.

Advantages Over Other Materials

| Material | Temperature Range | Performance at High Temperatures |

|---|---|---|

| Polytetrafluoroethylene (PTFE) | -60°C to 250°C | High performance without degradation |

| Rubber | -40°C to 120°C | Loses flexibility and strength under heat |

| PVC | -10°C to 60°C | Warps and softens under high heat |

| Metal | -20°C to 300°C | Expands under extreme temperatures, affecting performance |

As the table above demonstrates, Polytetrafluoroethylene tube can handle significantly higher temperatures compared to rubber and PVC, which makes it perfect for environments that regularly encounter extreme heat.

2. Excellent Chemical Resistance

PTFE Tube’s Superior Chemical Stability

In addition to its high-temperature resistance, another standout property of Polytetrafluoroethylene tube is its chemical inertness. PTFE tubes have unparalleled resistance to aggressive chemicals, solvents, acids, and bases. This makes them ideal for environments where exposure to harsh chemicals is frequent and unavoidable.

Unlike rubber or metals, which may degrade or corrode when exposed to aggressive substances, PTFE tubes maintain their structural integrity and do not react with most chemicals. This stability ensures that they remain functional over the long term without leaching harmful substances into the system, which is particularly important in chemical processing, pharmaceutical manufacturing, and laboratories.

Key Characteristics

- Acid Resistance: PTFE tubes are highly resistant to both strong acids and bases, making them ideal for laboratory environments where these chemicals are common.

- Solvent Resistance: PTFE’s structure makes it immune to the majority of organic solvents, unlike metals and rubber, which may degrade in such conditions.

- Corrosion Resistance: Even in highly corrosive settings, PTFE maintains its strength and longevity, ensuring it doesn’t compromise system integrity.

Applications of PTFE Tubes in Chemical Environments

- Chemical processing: In chemical reactors, PTFE tubes transport volatile or corrosive materials without risk of contamination.

- Pharmaceutical manufacturing: PTFE tubes are essential for transferring chemicals, solvents, and pharmaceutical ingredients safely, as they do not react with the substances.

- Food processing: PTFE is also used for food-grade applications where exposure to acidic substances (such as vinegar and citrus) is frequent.

Comparison to Other Materials

| Material | Chemical Resistance | Resistance to Acids & Bases | Resistance to Organic Solvents |

|---|---|---|---|

| Polytetrafluoroethylene (PTFE) | Excellent | High | High |

| Rubber | Poor | Low | Moderate |

| Stainless Steel | Moderate | Moderate | Moderate |

As the table shows, Polytetrafluoroethylene tube significantly outperforms rubber and stainless steel in terms of chemical resistance, particularly when exposed to both organic solvents and aggressive acids or bases.

3. Flexibility and Durability in Harsh Environments

Durability and High-Pressure Resistance

In addition to its exceptional resistance to high temperatures and corrosive chemicals, Polytetrafluoroethylene (PTFE) tube excels in its flexibility and durability under extreme conditions. PTFE tubes are built to withstand high-pressure systems without compromising their structural integrity, making them indispensable in critical applications that require both resilience and performance.

Due to the braided structure of the tube—often reinforced with materials like stainless steel wire or aramid fibers—PTFE tubes possess remarkable resistance to both abrasion and high pressure. This combination allows PTFE tubes to maintain peak performance even in highly demanding industrial environments. The braided reinforcement enhances the tensile strength of the tube, which ensures it remains intact and functional even under extreme pressure, making it an excellent choice for industries such as automotive, pharmaceuticals, electronics, chemical manufacturing, and aerospace.

For instance, PTFE tubes can endure tensile forces up to 180kg without sustaining damage. This high tensile strength significantly reduces the likelihood of material failure, ensuring that systems remain operational without frequent replacements. As a result, PTFE tubes offer long-term cost savings for businesses, as they require less maintenance and reduce operational downtime.

The Self-Locking Spiral Hose Protection

A standout feature of Polytetrafluoroethylene tube is its self-locking spiral hose protection, typically made from high-quality stainless steel. This protective layer further enhances the durability of the tube, ensuring it is shielded against physical damage caused by pressure, abrasion, impacts, or vibrations. The self-locking mechanism works by tightly securing the tube, preventing any undesired loosening or damage under stress.

This innovative feature makes PTFE tubes particularly useful in high-pressure and vibration-prone environments, such as hydraulic systems, fuel lines, and pressure vessels, where the tube is likely to be exposed to both mechanical stress and high internal pressure.

The stainless steel construction of the protective layer further ensures that the tube remains protected from external forces, significantly extending the service life of the tube and reducing the risk of system failure due to material wear.

Flexibility in Harsh Conditions

One of the unique properties of Polytetrafluoroethylene tube is its flexibility, which distinguishes it from other materials like metal pipes or rigid plastic tubing. Despite its high tensile strength and durability, PTFE tube maintains excellent flexibility, even under high-pressure conditions. This ensures that PTFE tubes are easy to install, even in tight spaces or systems with complex designs.

Unlike rigid materials that may crack or fracture when subjected to bending or movement, Polytetrafluoroethylene tube retains its shape and flexibility. This characteristic makes it ideal for use in applications where systems need to accommodate movement or shifting, such as automotive fuel lines, robotic systems, and machinery in motion. In these situations, the flexibility of PTFE tubes allows them to move and bend without sacrificing performance, even when exposed to extreme temperatures or corrosive substances.

Cost-Effective and Long-Term Durability

One of the most compelling reasons why Polytetrafluoroethylene tube is a preferred material in various industries is its long-term durability. Because PTFE tubes are so resistant to wear, abrasion, and pressure, they do not require frequent replacements, which significantly lowers maintenance costs over time.

In industries where system reliability is paramount—such as aerospace, chemical processing, or pharmaceutical production—the ability to reduce downtime and maintenance costs is critical. Frequent tube replacements or system failures can lead to costly operational halts, increased labor costs, and lost production time. Polytetrafluoroethylene tubes are designed to endure long-term use, ensuring that systems run smoothly without the need for constant maintenance or part replacement.

Furthermore, PTFE tubes are cost-effective in the long run. The initial investment in PTFE tubes may be higher than that of conventional materials, but their durability, performance, and reliability more than make up for the cost over time. The reduced need for replacements, maintenance, and repairs translates into significant savings for businesses, making PTFE tubes an economical solution for industries with demanding requirements.

Key Advantages in Harsh Environments

To summarize the distinct advantages of Polytetrafluoroethylene tube in harsh environments:

- Flexible Design: PTFE tubes can be easily routed through tight spaces and installed in complex systems, even under high-pressure conditions, which makes installation and maintenance simpler and faster.

- High Abrasion Resistance: Thanks to the reinforced braided structure and self-locking spiral hose protection, PTFE tubes can withstand physical stress, reducing the risk of damage from external forces such as abrasion, impacts, or vibrations.

- Tensile Strength: PTFE tubes can endure high tensile forces without failing, making them perfect for fluid transfer in systems where both pressure and mechanical stress are common.

- Vibration Resistance: The flexibility of PTFE tubes makes them ideal for vibration-prone applications, ensuring that they remain intact even in systems exposed to constant movement and stress.

Conclusion

Polytetrafluoroethylene tubes are designed to meet the most demanding industrial requirements, providing exceptional performance under extreme conditions. Whether it’s the ability to withstand high temperatures, resist corrosive chemicals, or maintain flexibility and durability under pressure, PTFE tubes have proven themselves to be far superior to other materials in a variety of applications. Industries such as aerospace, pharmaceuticals, and chemical processing all rely on PTFE tubes for their reliability, longevity, and performance in challenging environments.

As businesses continue to seek materials that offer both cost-effectiveness and exceptional performance, Polytetrafluoroethylene tube is undoubtedly a top contender for applications requiring high heat resistance, chemical stability, and durability.

FAQ

1. What makes Polytetrafluoroethylene tube resistant to high temperatures?

Polytetrafluoroethylene tubes are made from a polymer with a unique molecular structure that allows them to maintain their physical properties across a broad temperature range, from -60°C to 250°C.

2. Can Polytetrafluoroethylene tube be used in corrosive chemical environments?

Yes, PTFE has excellent resistance to a wide range of chemicals, including strong acids, bases, and organic solvents, making it ideal for environments with harsh chemical exposure.

3. How does Polytetrafluoroethylene tube compare to rubber hoses in flexibility?

PTFE tubes are more flexible than rubber hoses, even in high-pressure or high-temperature environments. They retain their flexibility without cracking or stiffening over time.

4. What are the benefits of Polytetrafluoroethylene tube in high-pressure systems?

Polytetrafluoroethylene tubes can withstand high pressure without compromising their structural integrity. Their durable braided construction makes them ideal for fluid transfer in systems with extreme pressure.

5. How long do Polytetrafluoroethylene tubes last?

With proper care and maintenance, PTFE tubes can last significantly longer than other materials. Their resistance to heat, chemicals, and pressure contributes to their long service life, minimizing replacement costs.