Table of Contents

Introduction

In the intricate world of industrial machinery and equipment, hydraulic systems stand as the backbone, transmitting immense power and pressure to drive crucial operations across diverse sectors. At the heart of these systems, connecting various components and ensuring the smooth flow of hydraulic oil, are hydraulic flange fittings. These indispensable key components play a vital role, acting as the circulatory system that allows hydraulic oil to efficiently transmit power and pressure. From heavy construction equipment to sophisticated manufacturing lines, the reliability of hydraulic flange fittings is paramount for the overall performance and safety of an entire system.

Despite their critical function, hydraulic flange fittings are often sources of frustration due due to persistent leakage issues. A single compromised connection can lead to significant downtime, environmental concerns, increased maintenance costs, and a loss of efficiency. The quest for a “zero leakage connection” is not just an aspiration but a fundamental requirement for optimal industrial operation. The challenge lies in ensuring ultra-long durability and accurate transfer through every connection point. This blog post will delve into the comprehensive strategies and advanced solutions, drawing on expert insights, to permanently resolve these issues and secure the integrity of your hydraulic flange fittings systems.

Understanding the Foundation of Leak-Proof Performance

The Criticality of Premium Materials for Durable hydraulic flange fittings

The longevity and reliability of hydraulic flange fittings begin with the fundamental choice of materials. Inferior materials are often the root cause of premature wear, corrosion, and structural failure, leading directly to leaks. A commitment to using the “best materials” is not merely a slogan but a strict adherence to quality that defines durable and trustworthy hydraulic flange fittings. For instance, certain critical parts of hydraulic flange fittings can be made from stainless steel material, such as 316L, which demonstrates no corrosion even after salt spray testing for ≥ 720 hours, significantly enhancing resistance to rust and corrosion.

This meticulous selection ensures that the hydraulic flange fittings can withstand demanding operational conditions, including high pressures and varying temperatures, for extended periods.

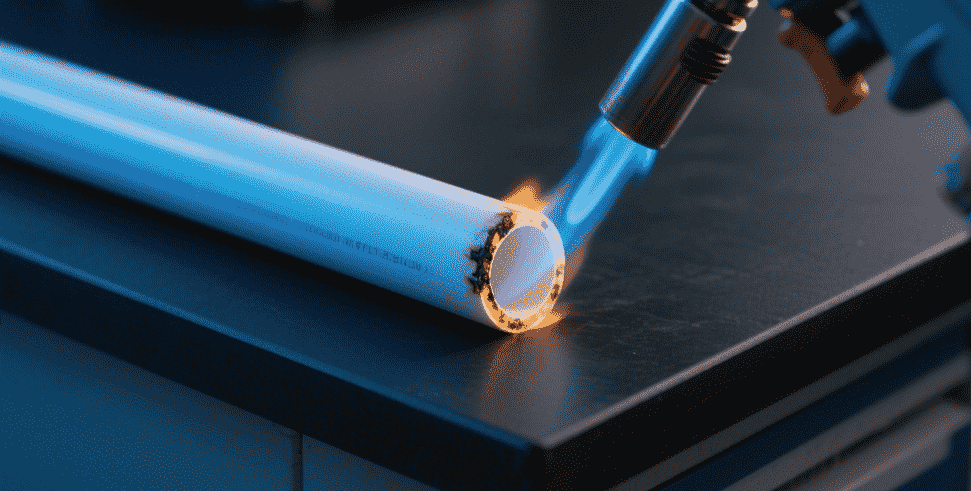

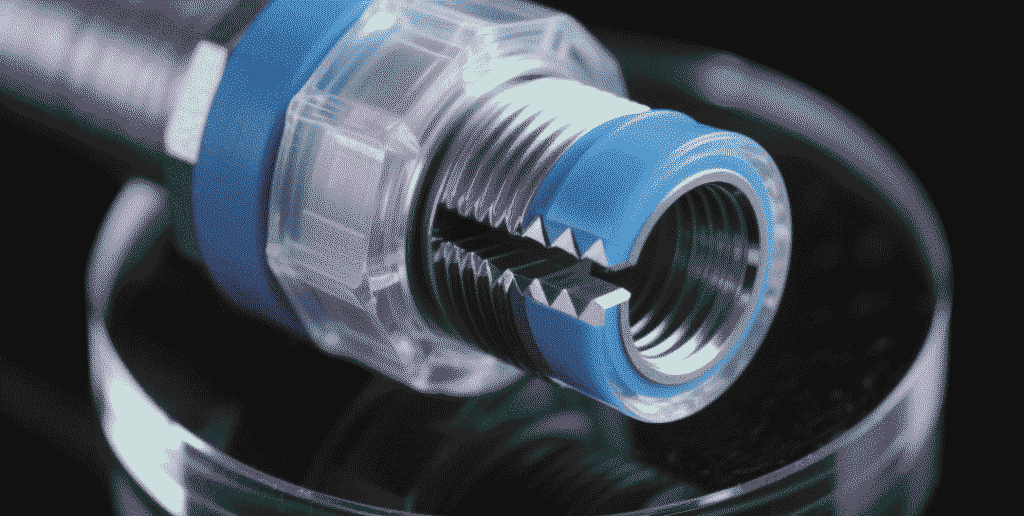

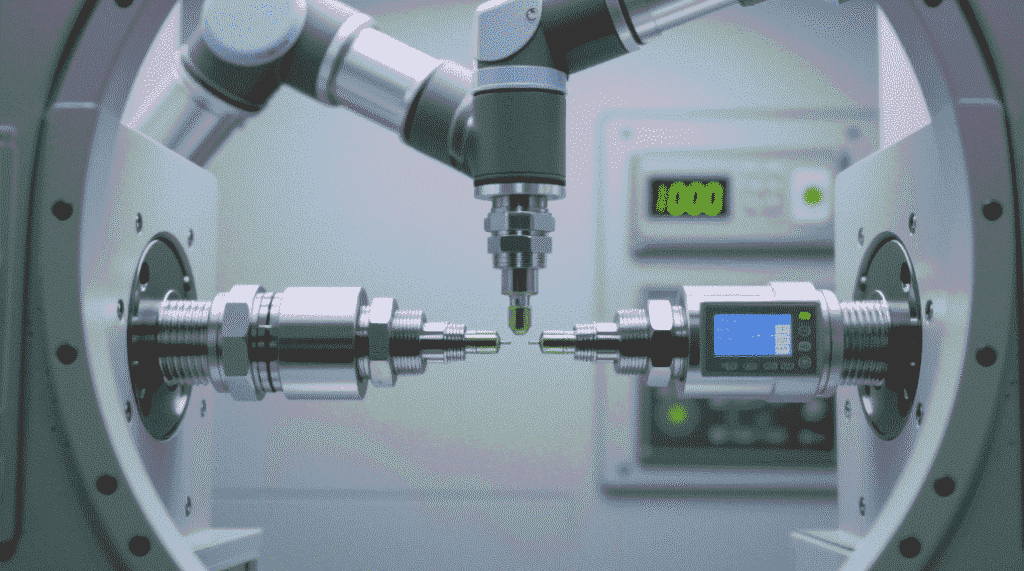

Precision Manufacturing: The Unseen Hero Behind Reliable hydraulic flange fittings

Beyond materials, the manufacturing process itself dictates the integrity of hydraulic flange fittings. Precision is key to achieving the tight tolerances and flawless finishes required for a leak-proof seal. Advanced processes like precision forging and laser welding are crucial technologies that ensure the accuracy and durability of products. From initial production to mass production, a closed loop of intelligent manufacturing is defined, ensuring consistency and excellence. Companies that leverage strong engineering capabilities and precision manufacturing processes are better equipped to produce highly specialized custom stainless steel hydraulic components that meet stringent client needs across various industries. This dedication to craftsmanship minimizes defects and strengthens the overall structure of the hydraulic flange fittings, contributing directly to a zero-leakage guarantee.

Upholding Quality: Certifications and Standards for Superior hydraulic flange fittings

For hydraulic flange fittings to truly be considered reliable, they must pass rigorous quality control and adhere to international standards. A comprehensive manufacturing and testing system is essential to ensure product quality. Production must strictly follow established standards such as GB/T, ASME, and DIN. Furthermore, products should undergo stringent testing according to a quality management system to ensure customer satisfaction. International certifications such as IP68 waterproof, CE, UL, and ROHS provide verifiable proof of a product’s quality, safety, and environmental compliance, offering peace of mind that the hydraulic flange fittings are built to last and perform under challenging conditions. These certifications are a testament to a manufacturer’s commitment to delivering industrial-grade hydraulic adapters with ultra-long durability.

Advanced Solutions for Common hydraulic flange fittings Issues

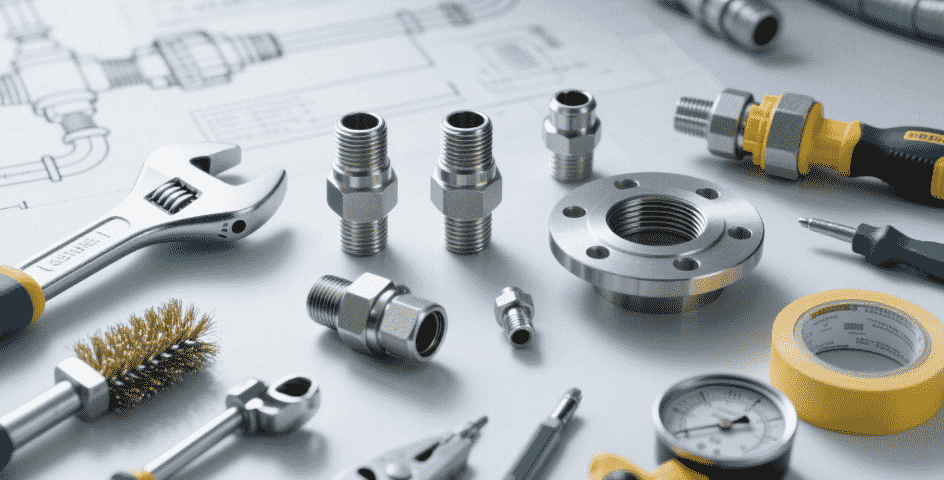

Addressing the common problems associated with hydraulic flange fittings requires a multi-faceted approach, combining proper component selection, meticulous installation, and effective maintenance strategies.

Tackling Frequent Leakage in Your hydraulic flange fittings Connections

Frequent leakage after installation is a pervasive issue that can severely impact system efficiency. To completely solve this, it’s advised to replace the existing hydraulic flange fitting with a new one. Crucially, before installing the new component, thoroughly clean any welding slag and oil stains from inside the pipe using kerosene or anhydrous ethanol. This ensures that the sealing surface is free of impurities, which are common culprits behind persistent leaks.

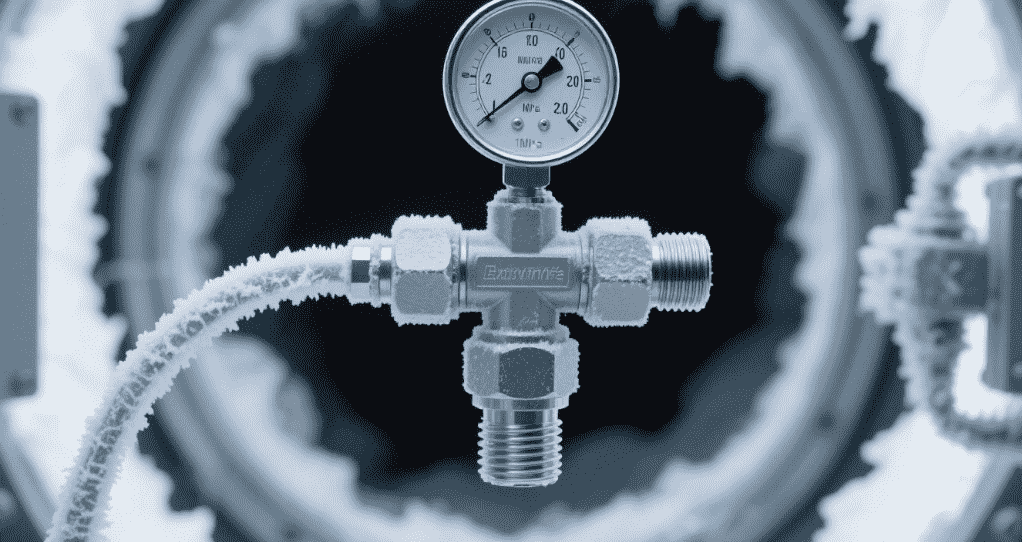

Comprehensive Strategies for Rust and Corrosion Prevention in hydraulic flange fittings

Rusting of hydraulic flange fittings threads after long-term use can make disassembly extremely difficult and compromise the connection’s integrity. To prevent this, surface strengthening treatments are highly effective. Options include plating the thread with hard chromium, to a thickness of at least 0.02mm, or coating it with molybdenum disulfide lubricant, which is suitable for working conditions between -20℃ and 200℃. As mentioned, using stainless steel materials like 316L for key parts offers superior corrosion resistance, enduring over 720 hours in salt spray tests without corrosion.

For ongoing rust prevention management, it is recommended to install a moisture-proof silicone bag during storage and apply rust proof oil to contact surfaces. Regular checks on the cleanliness of the threads, perhaps by blowing with high-pressure gas to prevent impurity accumulation, are also beneficial. In emergency scenarios where threads have already rusted, WD-40 penetrant can soften the rust, allowing for cleaning with a nylon brush. Severe corrosion, however, may necessitate cutting off the damaged section and re-tapping.

Achieving Perfect Thread Alignment in Multi-Joint hydraulic flange fittings Systems

Thread misalignment during the installation of multi-joint systems can lead to hydraulic oil leakage. Standardized control measures are vital to prevent this. Establishing a thread identification system, such as laser printing “NPT-1/2-28UNF” directly on the hydraulic flange fitting, can significantly reduce errors. Providing a size comparison table that includes ISO/ANSI/DIN standard conversion parameters further aids in accurate selection and installation.

Precision detection equipment is also instrumental. Utilizing an electronic thread gauge with an accuracy of ± 0.01mm to detect the tooth profile angle (60° or 55°) ensures compatibility. Additionally, verifying that the ovality of the tube body is ≤ 0.05mm is important, and submitting samples for retesting before procurement is recommended.

Selecting the Optimal hydraulic flange fittings for High-Pressure and Impact Conditions

Choosing the correct hydraulic flange fittings is paramount to avoid the risk of system shutdown due to joint rupture, especially in high-voltage systems. An accurate selection guide dictates that the working pressure should be ≤ 80% of the nominal pressure of the hydraulic flange fitting. For example, a 50MPa grade hydraulic flange fitting should be selected for a 35MPa system. For impact conditions, an additional 30% margin should be added. In high-temperature environments, the pressure needs to be converted based on the temperature coefficient, typically reduced by 20% for every 100℃ increase.

Strengthening testing verification is another crucial step. Requiring a third-party pressure pulse test report, demonstrating no leakage after 100,000 0.5Hz square wave tests, provides assurance of durability. Adding safety relief valves to critical areas, with a set value less than 10% of the maximum system pressure, offers an extra layer of protection. Structural optimization suggestions include adopting a double-layer sealing structure (main seal + buffer ring) to absorb pressure fluctuations and using thickened pipe wall material, such as high-pressure hose joint SC5S with an outer diameter ≥ 25mm.

Here’s a summary of key solutions for common hydraulic flange fittings problems:

| Problem | Recommended Solution Strategies |

| Frequent Leakage | Replacement & Cleaning: Replace the hydraulic flange fitting and thoroughly clean welding slag and oil stains from the pipe with kerosene or anhydrous ethanol before installation to ensure a clean sealing surface. |

| Rusting Threads / Disassembly Difficulty | Surface Treatment: Plate with hard chromium (≥ 0.02mm) or coat with molybdenum disulfide lubricant (-20~200℃). Material Selection: Use stainless steel (e.g., 316L) for key parts (≥ 720 hrs salt spray without corrosion). Rust Prevention: Install moisture-proof silicone bags, apply rust proof oil, regularly check thread cleanliness. Emergency: WD-40 penetrant, nylon brush, or re-tapping. |

| Thread Misalignment / Oil Leakage | Standardization: Establish thread identification systems (laser print “NPT-1/2-28UNF”) and provide size comparison tables (ISO/ANSI/DIN conversions). Precision Detection: Use electronic thread gauges (accuracy ± 0.01mm) for tooth profile angle (60°/55°) and ensure tube body ovality ≤ 0.05mm. Professional Guidance: Use torque step method and hydraulic torque wrench. |

| Rupture in High-Voltage Systems | Accurate Selection: Working pressure ≤ 80% nominal pressure; add 30% margin for impact; convert pressure for high-temperature environments (reduce 20% per 100℃). Testing: Require third-party pressure pulse test reports (no leakage after 100,000 0.5Hz square wave tests); add safety relief valves (<10% max system pressure). Optimization: Double-layer sealing structure; thickened pipe wall material (e.g., SC5S outer diameter ≥ 25mm). |

Mastering Installation: Key to Long-Term Reliability of hydraulic flange fittings

Even the highest quality hydraulic flange fittings can fail if not installed correctly. Proper installation practices are crucial for ensuring leak-free performance and maximizing system efficiency.

Essential Preparation for Flawless hydraulic flange fittings Installation

Before commencing any installation, thorough preparation is non-negotiable. As highlighted for leakage prevention, it is critical to “thoroughly clean the welding slag and oil stains inside the pipe with kerosene or anhydrous ethanol before installation to ensure that the sealing surface is free of impurities”. This preliminary step prevents microscopic contaminants from compromising the seal, which can otherwise lead to premature failure of the hydraulic flange fittings. Ensuring all components are clean and free from damage is foundational for a successful, long-lasting connection.

The Torque Step Method: Ensuring Optimal Seal Integrity for hydraulic flange fittings

Achieving the correct torque during assembly is vital for the seal integrity of hydraulic flange fittings. The “torque step method” is a professional installation guidance technique that ensures precise and secure tightening. This method involves a gradual application of torque: starting with an “initial torque 50%,” progressing to a “compound torque 100%,” and concluding with a “final torque 120%”. This phased approach allows the hydraulic flange fitting to seat properly and the sealing elements to compress evenly, preventing overtightening that could damage threads or components, and undertightening that leads to leaks.

Leveraging Specialized Tools for Accurate hydraulic flange fittings Assembly

To achieve the precise torque specified by the step method, the use of specialized tools is highly recommended. It is advisable to “use a hydraulic torque wrench (with an accuracy of ± 3%) in conjunction with a fixed torque socket”. These tools provide the accuracy needed to meet exacting torque specifications, eliminating guesswork and significantly reducing the risk of installation errors. Professional tools ensure that each hydraulic flange fitting is secured to its optimal tension, which is a critical factor in preventing future leaks and ensuring the system’s overall reliability and ultra-long durability. Adopting these 6 essential tips for hydraulic connector installation can truly maximize your system’s efficiency.

The Hebei Minglai Difference: Your Partner for Unwavering hydraulic flange fittings Performance

For industries seeking reliable and durable hydraulic flange fittings, choosing the right manufacturer is as crucial as the product itself. Hebei Minglai Pipe Fittings Co., Ltd. stands out as a professional connector manufacturer dedicated to delivering high-performance solutions.

Tailored Customization for Unique hydraulic flange fittings Requirements

Every hydraulic system has its unique demands, and off-the-shelf solutions may not always suffice. Hebei Minglai Pipe Fittings Co., Ltd. excels in providing “customized service,” tailoring hydraulic connectors according to specific customer needs. They are dedicated to offering “highly specialized custom stainless steel hydraulic components,” leveraging strong engineering capabilities to address diverse requirements. This flexibility, coupled with the support for customization, ensures that clients across various industries receive hydraulic flange fittings that perfectly integrate into their systems, effectively solving personalized needs. This commitment extends beyond mere production, encompassing product design, manufacturing, and performance testing.

Driving Innovation Through R&D and Smart Manufacturing of hydraulic flange fittings

Innovation is at the core of Hebei Minglai’s philosophy. The company recognizes that “technology drives the future, innovation leads change,” making R&D a core competitiveness. With a professional design team possessing independent development capabilities, they are constantly pushing the boundaries of what hydraulic flange fittings can achieve. Their approach to “smart manufacturing” defines a closed loop “from production to mass production,” ensuring consistent quality and efficiency. This dedication to research and development allows them to provide efficient, energy-saving, and reliable hydraulic solutions, keeping them at the forefront of the industry.

End-to-End Support and Service for Your hydraulic flange fittings Investments

Hebei Minglai Pipe Fittings Co., Ltd. prides itself on offering comprehensive support that goes beyond the sale of hydraulic flange fittings. Their services encompass “full lifecycle technical support and after-sales service,” aiming to help clients improve system efficiency, reduce maintenance costs, and shorten project cycles. They provide “rapid service response” and ensure customer satisfaction as their ultimate goal. Customers like Harrison Atkinson from Lokamart have praised the quality of their bulk-purchased hydraulic joints, noting that they “far exceed expectations” and successfully “dispelled concerns” about leakage. This unwavering commitment to customer support, coupled with the proven reliability of their hydraulic flange fittings, positions Hebei Minglai as a trusted partner for long-term operational success.

FAQ

How can persistent leakage in hydraulic flange fittings after installation be completely solved?

To completely resolve frequent leakage in hydraulic flange fittings after installation, it is recommended to replace the hydraulic flange fitting with a new one. Prior to the new installation, thoroughly clean any welding slag and oil stains from inside the pipe using kerosene or anhydrous ethanol. This crucial step ensures that the sealing surface is entirely free of impurities, which are often the primary cause of leaks.

What measures prevent disassembly difficulties caused by rusting of hydraulic flange fittings threads over time?

To prevent the difficulty of disassembly caused by rusting of hydraulic flange fittings threads after long-term use, several measures can be taken. Surface strengthening treatments include plating the thread with hard chromium (thickness ≥ 0.02mm) or coating it with molybdenum disulfide lubricant, suitable for temperatures between -20℃ and 200℃. Key parts can also be manufactured from stainless steel materials like 316L, which resist corrosion for over 720 hours in salt spray tests.

For management, store hydraulic flange fittings with a moisture-proof silicone bag and apply rust proof oil to contact surfaces. Regularly check thread cleanliness, perhaps by blowing with high-pressure gas. For rusted threads, WD-40 penetrant can soften rust for cleaning with a nylon brush; severe corrosion may require cutting and re-tapping.

How should hydraulic flange fittings be chosen to avoid rupture risks in high-voltage systems?

To choose hydraulic flange fittings and avoid the risk of rupture in high-voltage systems, an accurate selection guide is crucial. Ensure the working pressure is ≤ 80% of the nominal pressure of the hydraulic flange fitting (e.g., a 50MPa grade fitting for a 35MPa system). Add an additional 30% margin for impact conditions, and convert pressure based on the temperature coefficient for high-temperature environments (reducing by 20% for every 100℃).

Strengthen testing verification by requiring third-party pressure pulse test reports (e.g., no leakage after 100,000 0.5Hz square wave tests). Consider structural optimization with a double-layer sealing structure (main seal + buffer ring) to absorb pressure fluctuations and use thickened pipe wall material (e.g., high-pressure hose joint SC5S with an outer diameter ≥ 25mm).

How can hydraulic oil leakage due to thread misalignment in multi-hydraulic flange fittings systems be prevented?

To avoid hydraulic oil leakage caused by thread misalignment during the installation of multi-hydraulic flange fittings systems, standardized control measures are essential. Establish a thread identification system, such as laser printing the thread specification (e.g., “NPT-1/2-28UNF”) on the hydraulic flange fitting. Provide a size comparison table, including ISO/ANSI/DIN standard conversion parameters, for accurate reference. Utilize precision detection equipment like an electronic thread gauge (accuracy ± 0.01mm) to detect the tooth profile angle (60° or 55°), and ensure the ovality of the tube body is ≤ 0.05mm. Professional installation guidance, such as adopting the torque step method (initial 50% → compound 100% → final 120%) and using a hydraulic torque wrench (accuracy ± 3%) with a fixed torque socket, is also highly recommended.

Conclusion

A Future of Reliability: Embracing Leak-Free hydraulic flange fittings Systems

The aspiration for a “zero leakage connection” with “ultra long durability” is not just a dream but an achievable reality for modern industrial hydraulic systems. By understanding the critical role of material quality, embracing precision manufacturing, adhering to rigorous quality control standards, and implementing meticulous installation practices, the pervasive issues of leaks, rust, and rupture in hydraulic flange fittings can be effectively eliminated. The commitment to “accurate transfer” and “expert in industrial grade hydraulic adapters” means that industries can look forward to significantly improved system efficiency, reduced maintenance costs, and shortened project cycles, ultimately leading to greater operational success.

Taking the Next Step Towards Optimal hydraulic flange fittings Performance

For businesses seeking to fortify their hydraulic infrastructure and ensure the unwavering reliability of their operations, partnering with a professional and innovative manufacturer like Hebei Minglai Pipe Fittings Co., Ltd. is a strategic decision. With their dedication to customized solutions, advanced R&D, smart manufacturing, and comprehensive full-lifecycle technical support, they provide not just hydraulic flange fittings, but complete and efficient hydraulic solutions. By choosing a supplier that prioritizes innovation, quality, and customer satisfaction, you can truly unlock the secret to ending hydraulic flange fittings leaks forever, securing the future performance and longevity of your critical systems.