Table of Contents

Introduction

In the robust world of industrial machinery and complex hydraulic systems, precision and reliability are not just desired traits—they are absolute necessities. At the heart of many hydraulic networks lies the humble yet critical Tee connector, often responsible for diverting fluid flow and maintaining system integrity under immense pressure. While seemingly straightforward, high-pressure Tee fittings are susceptible to two major dangers: rupture and leakage. These issues can lead to catastrophic system failures, costly downtime, and significant safety hazards.

This expert safety guide aims to illuminate these critical risks and provide comprehensive strategies to eliminate them, ensuring the longevity, efficiency, and safety of your hydraulic operations. By understanding the intricacies of Tee selection, installation, and maintenance, businesses can safeguard their investments and uphold operational excellence.

What is a Tee?

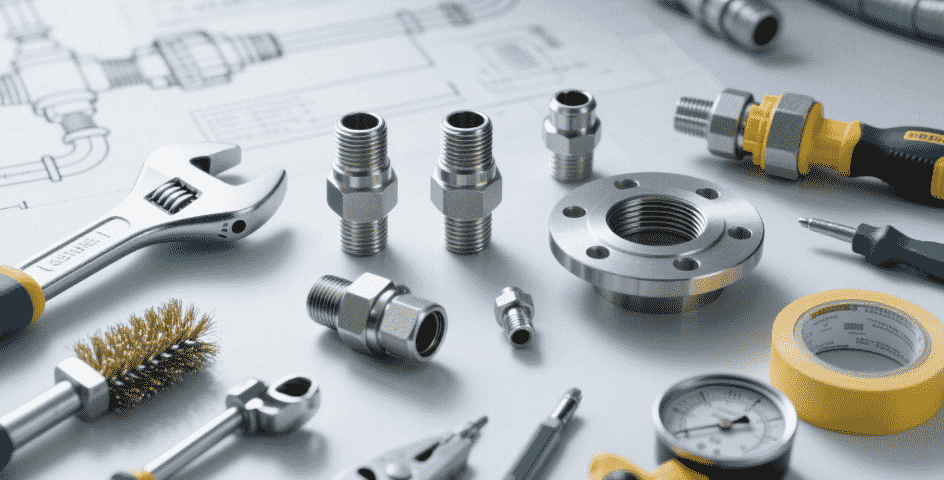

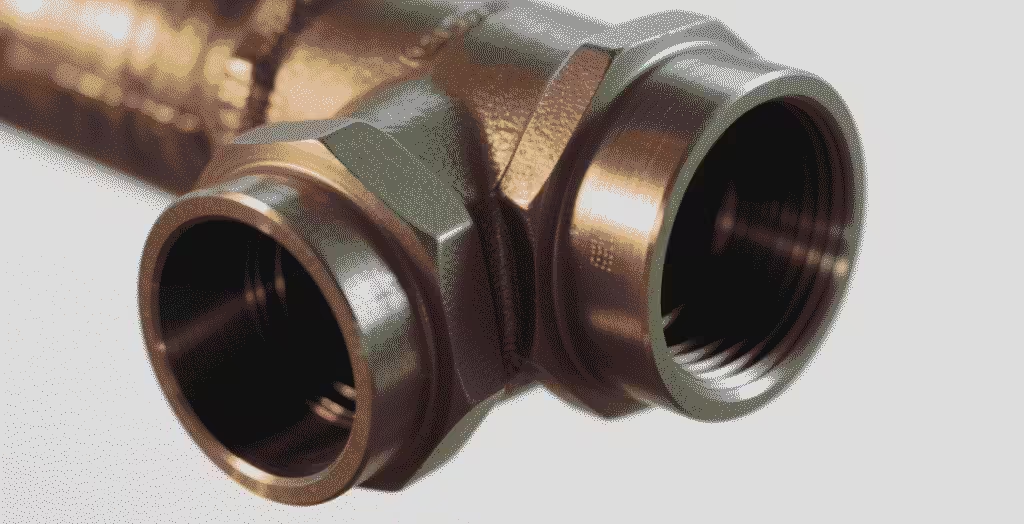

A Tee, in the context of hydraulic systems, is a type of pipe fitting that takes its name from its ‘T’ shape. It features two outlets, with the main line and the branch line typically at 90-degree angles. Its primary function is to combine or divide fluid flow within a pipeline, making it an indispensable component for creating complex hydraulic networks. Hydraulic joints, including this type of connector, are essential for connecting the hydraulic system to ensure that the hydraulic oil can transmit power and pressure efficiently throughout the machinery.

Given their role in critical points of fluid diversion, these connectors are subjected to the same, if not greater, stresses as the main pipelines, especially in high-pressure applications where integrity is paramount.

Understanding the 2 Major High-Pressure Tee Dangers

High-pressure hydraulic systems demand components that can withstand extreme forces. When a Tee component fails in such an environment, the consequences can range from minor operational inefficiencies to severe accidents. The two primary dangers associated with high-pressure Tee fittings are rupture (or bursting) and leakage. Both can compromise system performance, cause environmental contamination, and pose significant safety risks to personnel.

Tee Burst/Rupture: The Catastrophic Failure

The rupture of a high-pressure Tee component is perhaps the most dangerous form of failure. It can lead to sudden loss of hydraulic fluid, rapid depressurization, and potentially projectile fragments, posing an immediate threat to life and property. Eliminating this risk requires meticulous attention to selection, design, and verification.

- Understanding Rated Pressure: Why Working Pressure Should Not Exceed 80% Nominal Value? A fundamental principle in preventing fitting rupture is to ensure that the actual working pressure of the system does not exceed 80% of the nominal pressure of the Tee component. For instance, if a system operates at 35MPa, a connector rated for 50MPa should be selected. This 20% safety margin accounts for unforeseen pressure spikes, minor material imperfections, and general wear and tear, acting as a critical buffer against catastrophic failure.

- Impact Conditions and Component Selection: 30% Safety Margin Importance Hydraulic systems often experience dynamic impact conditions, such as sudden starts, stops, or changes in flow direction, which can generate significant pressure surges. Under such circumstances, an additional 30% safety margin should be incorporated into the selection process. This extra allowance ensures the Tee fitting can absorb and withstand these transient, high-stress events without succumbing to fatigue or immediate rupture.

- High-Temperature Environment: Effects on Pressure Resistance and Derating Temperature plays a critical role in the material properties of hydraulic components. High-temperature environments can significantly reduce the tensile strength and overall integrity of a Tee component. For every 100℃ increase in temperature, the pressure rating of the fitting should be reduced by 20%. This derating factor is crucial for preventing material degradation and ensuring that the Tee maintains its structural integrity under elevated thermal conditions.

- Third-Party Pressure Pulse Test Report: Key Evidence for Tee High-Pressure Safety Reliable Tee fittings are not merely manufactured; they are rigorously tested. A third-party pressure pulse test report serves as crucial evidence of a component’s ability to withstand dynamic pressures. These tests simulate real-world operational stresses, verifying that the Tee can endure repeated pressure cycles without failure.

- 100,000 0.5Hz Square Wave Tests: Gold Standard for Reliability One specific and highly stringent test for hydraulic components is the 100,000 0.5Hz square wave test. This involves subjecting the Tee component to 100,000 cycles of pressure pulses at 0.5 Hertz with a square wave profile. Successfully passing such a test, with no leakage, indicates exceptional durability and resistance to fatigue, making it a gold standard for verifying the reliability of Tee fittings in high-pressure systems.

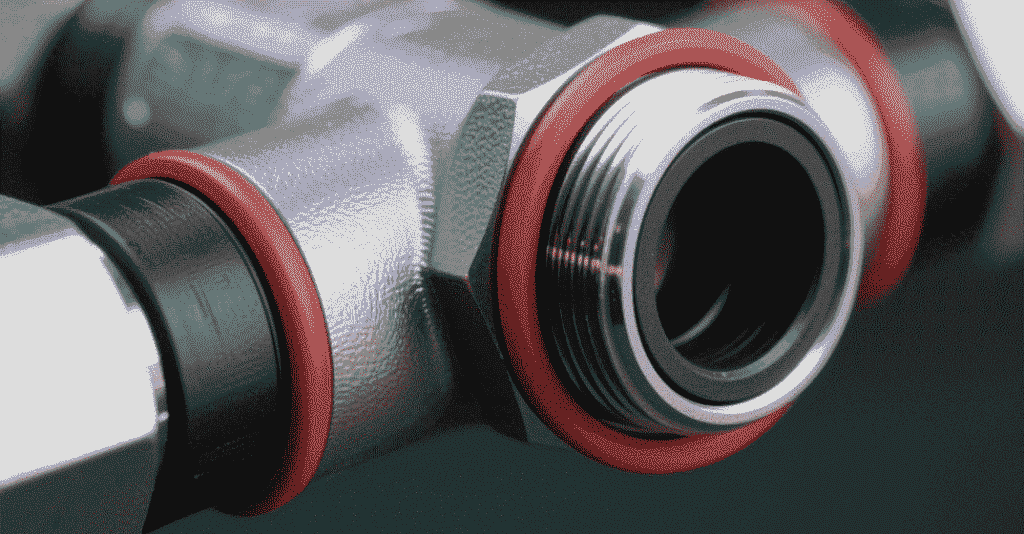

- Double-Layer Sealing Structure: Absorbing Pressure Fluctuations to Boost Burst-Proof Performance Innovative design features can significantly enhance a Tee component’s resilience. The adoption of a double-layer sealing structure, which often includes a main seal and a buffer ring, is a prime example. This design helps absorb and dissipate pressure fluctuations more effectively, distributing stress and greatly improving the burst-proof performance of the fitting.

- Thickened Pipe Wall Material: Core Strategy for Structural Optimization For applications demanding the highest pressure resistance, structural optimization through thickened pipe wall material is a core strategy. For example, a high-pressure hose joint like the SC5S type requires an outer diameter of at least 25mm to ensure robust performance under extreme pressures. Increased material thickness directly translates to greater strength and resistance against internal forces that could lead to rupture.

- Safety Relief Valves: The Last Line of Defense in High-Pressure Tee Systems Despite all preventive measures, overpressure events can still occur. In critical areas, installing safety relief valves is essential. These valves act as the last line of defense, automatically releasing excess pressure when it exceeds a predetermined threshold. It is crucial that the set value of these relief valves is less than 10% of the maximum system pressure, ensuring they activate before the Tee component reaches its failure point.

- Material Selection for the Connector: Crucial Decision to Prevent Rupture The quality and type of material used in the manufacturing of a hydraulic joint are paramount. Utilizing the best materials, such as high-grade stainless steel (e.g., 316L) or specific alloys, is a fundamental step in ensuring the Tee connector can withstand high pressures without rupturing. Professional manufacturers prioritize material quality, subjecting products to strict testing to ensure compliance with quality management systems.

Tee Leakage: The Insidious System Degrader

While less immediately catastrophic than a rupture, leakage from a high-pressure Tee fitting can be equally damaging over time. It leads to fluid loss, reduced system efficiency, environmental contamination, and potential safety hazards due to slippery surfaces or spray. Addressing leakage requires precision in installation, proper sealing, and diligent maintenance.

- Common Causes of High-Pressure Leakage: Improper Installation and Thread Misalignment Frequent leakage of hydraulic joints after installation is a common problem. Often, the primary culprits are improper installation techniques and thread misalignment. Even a slight discrepancy can prevent a perfect seal, allowing high-pressure fluid to escape over time.

- Thorough Pipe Cleaning: First Step for Leak-Proof Joint Installation Before installing any Tee fitting, it is imperative to thoroughly clean the inside of the pipe. This means removing all welding slag, oil stains, and any other impurities. Kerosene or anhydrous ethanol are effective agents for achieving this level of cleanliness. A pristine environment ensures that the sealing surfaces of the Tee and the pipe can make full, unobstructed contact.

- Ensuring Seal Surface Impurity-Free: Key for Zero-Leakage Connections Following pipe cleaning, meticulous attention must be paid to ensuring that the sealing surface of the Tee itself is entirely free of impurities. Even microscopic particles can create channels for fluid to escape under high pressure, compromising the integrity of the connection and leading to leaks.

- Thread Identification System: Importance of Laser Printing Parameters To avoid confusion and ensure correct matching of components, a standardized thread identification system is critical. Laser printing parameters like “NPT-1/2-28UNF” directly onto the joint provides clear and unambiguous information, reducing the risk of using incompatible threads.

- Precision Detection Equipment: Electronic Thread Gauge for the Connector Achieving a perfect seal relies on precise thread dimensions. Using an electronic thread gauge with an accuracy of ±0.01mm is essential for detecting the exact tooth profile angle (whether 60° or 55°) and ensuring perfect compatibility between the Tee connector and the mating part. This level of precision prevents misalignments that cause leaks.

- Tube Body Ovality Control: Guaranteeing Tight Fit for the Connector The ovality of the tube body to which the Tee connector is attached is another critical factor. Ideally, the ovality should be ≤ 0.05mm. Deviations from this tolerance can prevent a tight, uniform seal, leading to points of weakness where leaks can occur. It is recommended to submit samples for retesting before procurement to verify this critical dimension.

- Torque Step Method: Standardized Process for High-Pressure Installation Proper torque application is paramount for a leak-free connection. The torque step method is a professional installation guidance that involves gradually increasing torque in stages: initial torque at 50%, then compound torque at 100%, and finally, a finishing torque at 120%. This method ensures that the Tee joint is seated correctly and uniformly, preventing localized stress and potential leaks.

- Hydraulic Torque Wrench: Essential Tool for Precise Installation To execute the torque step method accurately, a hydraulic torque wrench is highly recommended. These tools offer an accuracy of ±3%, ensuring that the exact required torque is applied, thereby optimizing the sealing performance of the Tee connection and minimizing the risk of over-tightening or under-tightening. It should be used in conjunction with a fixed torque socket.

- High-Pressure Component Anti-Corrosion: Challenges and Solutions for Long-Term Operation Long-term exposure to operational fluids and environmental conditions can lead to corrosion, especially on threads. This corrosion can degrade sealing surfaces and make disassembly difficult. Effective anti-corrosion strategies are vital for maintaining the integrity and serviceability of the Tee component over its lifespan.

Expert Safety Guide: Eliminating Tee Dangers

Eliminating the dangers of rupture and leakage in high-pressure Tee fittings requires a multi-faceted approach, encompassing rigorous selection, precise installation, and ongoing maintenance. Leveraging expert knowledge and proven techniques, businesses can significantly enhance the safety and efficiency of their hydraulic systems.

Selecting the Right Tee for High-Pressure Applications

Choosing the appropriate Tee component is the first and most critical step in preventing failures. This involves careful consideration of materials, design, and verified performance.

- Material Optimization: Ensuring Excellence in High-Pressure Components The fundamental strength of any Tee component lies in its material. Manufacturers dedicated to excellence utilize the best materials, such as high-grade stainless steel (e.g., 316L) for enhanced corrosion resistance, or specialized alloys for extreme pressure and temperature applications. This ensures that the component can withstand the demanding conditions of high-pressure systems.

- Certifications and Standards: The Global Passport for Quality Reputable Tee fittings will adhere to international standards such as GB/T, ASME, and DIN, and possess certifications like IP68 waterproof, CE, UL, and ROHS. These certifications are not merely badges but represent rigorous testing and adherence to global quality and safety benchmarks, assuring buyers of the component’s reliability and suitability for intended use.

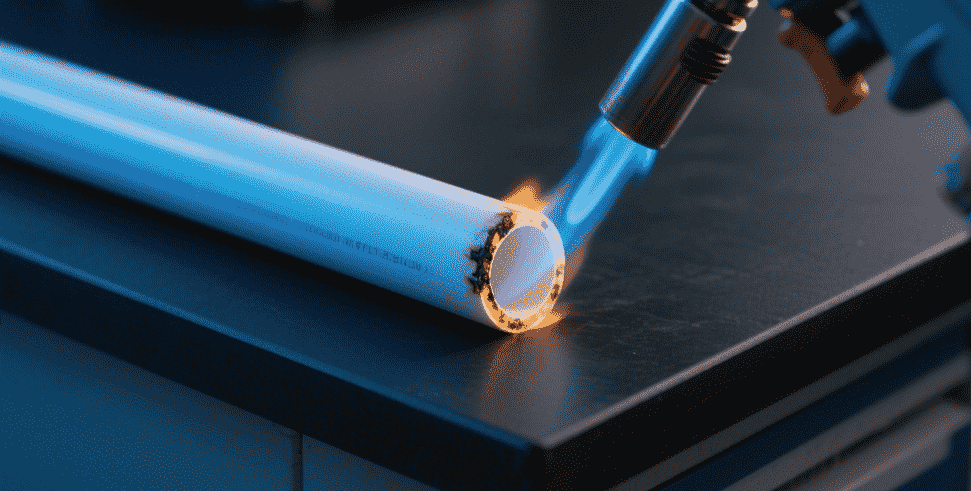

- Advanced Craftsmanship: Precision Forging and Laser Welding The manufacturing process directly impacts the quality and durability of a Tee component. Advanced processes such as precision forging and laser welding ensure product accuracy and enhance durability, critical factors for high-pressure applications. These techniques reduce material defects and create stronger, more reliable joints within the fitting itself.

- R&D Capability and Customization: Tailored Solutions for Complex Needs Some hydraulic systems have unique requirements that standard Tee fittings cannot meet. A manufacturer with strong R&D capabilities and the ability to support customization can provide tailored hydraulic components according to customer needs. This includes a professional design team with independent development capabilities, capable of providing full lifecycle technical support.

Precision Installation for Leak-Free Tee Systems

Even the highest quality Tee component can fail if installed incorrectly. Precision in installation is paramount for preventing leaks and ensuring the long-term integrity of the hydraulic system.

- Torque Step Method: Standardized Best Practice As previously discussed, the torque step method (initial 50% → compound 100% → final 120%) is a professional standard for installing Tee components. This systematic approach prevents over-tightening or under-tightening, distributing stress evenly and creating a secure, leak-proof seal.

- Hydraulic Torque Wrench: The Tool for Accuracy The use of a hydraulic torque wrench, with its precision of ±3%, is highly recommended to accurately apply the required torque during Tee installation. This tool ensures that each stage of the torque step method is executed with exactness, directly contributing to a robust, leak-free connection.

- Thorough Cleaning Protocol: Eliminating Contaminants Before any installation, both the pipe interior and the Tee’s sealing surfaces must be meticulously cleaned. Kerosene or anhydrous ethanol can remove welding slag, oil stains, and other impurities. Ensuring that all sealing surfaces are free of debris is fundamental to achieving a zero-leakage connection.

- Precision Detection Equipment: Electronic Thread Gauges and Ovality Checks Utilizing an electronic thread gauge (accuracy ±0.01mm) to verify thread angles (60° or 55°) and confirming tube body ovality (≤0.05mm) before procurement are vital steps. These checks ensure perfect component compatibility and prevent installation-related leaks.

| Parameter | Recommended Standard/Value | Significance for Tee Safety |

| Working Pressure Margin | ≤ 80% of Nominal Pressure (e.g., 35MPa system uses 50MPa rated fitting) | Prevents rupture due to pressure spikes and material fatigue. |

| Impact Condition Margin | +30% additional margin | Accounts for sudden pressure surges and dynamic stresses. |

| High-Temperature Derating | Reduce pressure rating by 20% for every 100℃ increase | Mitigates material degradation and maintains integrity at high temperatures. |

| Pressure Pulse Test | 100,000 0.5Hz square wave tests (no leakage) | Verifies dynamic pressure resistance and fatigue life. |

| Safety Relief Valve Setting | < 10% of maximum system pressure | Last line of defense against overpressure, prevents rupture. |

| Tee Thread Identification | Laser print “NPT-1/2-28UNF” on joint | Ensures correct component matching, prevents misalignment. |

| Thread Gauge Accuracy | Electronic thread gauge (accuracy ±0.01mm) | Guarantees precise thread dimensions for a tight seal. |

| Tube Body Ovality | ≤ 0.05mm | Ensures uniform sealing surface contact, prevents leaks. |

| Hard Chromium Plating | Thickness ≥ 0.02mm | Prevents thread rust and facilitates disassembly. |

| Salt Spray Test (316L SS) | ≥ 720 hours without corrosion | Confirms corrosion resistance for stainless steel components. |

Maintenance and Rust Prevention for Tee Joints

Long-term reliability of Tee components also hinges on effective maintenance and robust rust prevention strategies. These measures prevent degradation and ensure ease of serviceability throughout the system’s lifespan.

- Surface Strengthening Treatment: Plating and Lubrication To prevent rust-induced disassembly difficulties, surface strengthening treatments are crucial. This includes plating threads with hard chromium to a thickness of at least 0.02mm, which offers excellent corrosion resistance. Alternatively, coating threads with molybdenum disulfide lubricant is effective for specific working conditions ranging from -20℃ to 200℃.

- Stainless Steel Material (316L): A Robust Solution For key parts of the Tee component, especially those in harsh environments, using stainless steel material like 316L is highly recommended. This material demonstrates superior corrosion resistance, often showing no corrosion after a salt spray test for ≥ 720 hours, ensuring long-term integrity.

- Rust Prevention Management: Storage and Regular Checks Effective rust prevention extends to storage and routine maintenance. Installing moisture-proof silicone bags during storage and applying rust-proof oil to contact surfaces are simple yet effective measures. Furthermore, regularly checking the cleanliness of the threads, perhaps by blowing with high-pressure gas to prevent impurity accumulation, is essential.

- Emergency Response Plan for Rusted Threads Despite preventive efforts, threads can sometimes rust. In such cases, an emergency response plan is vital. Rusted threads can often be softened with WD-40 penetrant and then cleaned with a nylon brush. However, severe corrosion may necessitate cutting off the damaged section and re-tapping the thread, a more involved repair.

Conclusion

The safe and efficient operation of high-pressure hydraulic systems relies heavily on the integrity of every component, especially the critical Tee connector. By understanding and actively mitigating the two major dangers—rupture and leakage—through informed selection, precise installation, and diligent maintenance, businesses can achieve unparalleled reliability. From adhering to stringent pressure margins and demanding third-party test reports to implementing meticulous cleaning protocols and robust anti-corrosion strategies, every step contributes to a more secure and productive hydraulic environment. Investing in high-quality Tee fittings and expert installation practices is not merely a cost but an investment in the longevity, efficiency, and safety of your entire operation, ultimately leading to reduced maintenance costs and shortened project cycles.

FAQ

How can I completely solve the frequent leakage of hydraulic joints after installation?

To solve frequent leakage, replace the hydraulic joint with a new one. Before installation, thoroughly clean the welding slag and oil stains inside the pipe using kerosene or anhydrous ethanol to ensure that the sealing surface is entirely free of impurities. Proper torque application via the torque step method with a hydraulic torque wrench is also crucial.

How can I prevent the difficulty of disassembly caused by rusting of Tee component threads after long-term use?

Prevent rusting by applying surface strengthening treatments such as hard chromium plating (thickness ≥ 0.02mm) or coating with molybdenum disulfide lubricant. For key parts, consider 316L stainless steel, which has high corrosion resistance. Implement rust prevention management during storage (moisture-proof silicone bags, rust-proof oil) and regularly check thread cleanliness.

How do I choose a Tee component to avoid the risk of shutdown caused by rupture in a high-pressure system?

Choose a Tee component with a nominal pressure where the working pressure is ≤ 80%. Add an extra 30% margin for impact conditions and convert pressure based on temperature coefficients for high-temperature environments. Look for third-party pressure pulse test reports (e.g., 100,000 0.5Hz square wave tests) and consider fittings with double-layer sealing structures and thickened pipe walls. Ensure critical areas have safety relief valves set < 10% of maximum system pressure.

How do I avoid hydraulic oil leakage caused by thread misalignment during the installation of multi-joint systems?

Establish a thread identification system (laser printing parameters on the Tee component) and provide a size comparison table. Use precision detection equipment like an electronic thread gauge (accuracy ± 0.01mm) to check tooth profile angle and tube body ovality (≤ 0.05mm). Follow professional installation guidance, such as the torque step method, using a hydraulic torque wrench.