Key Takeaways

- Learn the 10 advanced stainless steel pipe coupling designs used in hydraulic systems

- Understand how coupling type impacts pressure rating, leakage control, corrosion resistance, and safety

- Compare coupling options through a practical selection table

- Discover real engineering data, design standards, and performance benchmarks

- Learn how coupling choice affects maintenance, installation time, and system efficiency

- Explore case studies and industry best practices

- Read an FAQ section with Google-style questions for better search relevance

Table of Contents

Introduction

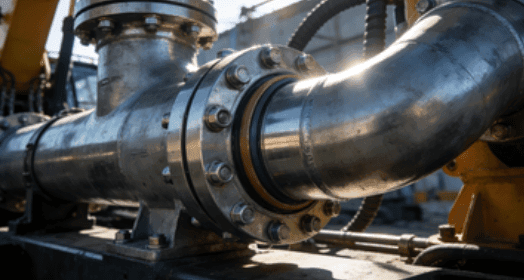

Hydraulic systems are among the most powerful industrial mechanisms on Earth. They generate massive forces through pressurized fluids—often reaching 3,000 to 7,500 psi (20–50 MPa) in common industrial applications. When a coupling fails, the result is not just downtime, but potential injury, environmental contamination, and costly repair. In fact, industry reports estimate that hydraulic coupling failure accounts for over 25% of hydraulic system leaks, causing billions of dollars in annual losses globally.

That is why choosing the right stainless steel pipe coupling is not a matter of convenience—it is a safety and performance decision. Stainless steel offers superior corrosion resistance, durability, and pressure tolerance compared to brass or carbon steel. But the coupling design itself—whether threaded, crimped, flanged, or quick-connect—determines how effectively the system can handle vibration, pressure spikes, thermal expansion, and frequent disassembly.

In this article, you will learn the 10 advanced stainless steel pipe coupling designs that dominate modern hydraulic systems. You’ll also gain deep insight into how to select the right coupling for your application, supported by real engineering data and design standards.

The Hydraulic Reality: Why Stainless Steel Couplings Are Critical

Corrosion Resistance and System Longevity

Hydraulic systems often operate in harsh environments: chemical plants, marine vessels, mining, and heavy construction. Moisture, salt, and hydraulic fluid additives can cause rapid corrosion in ordinary steel. Stainless steel (such as 304, 316, or duplex grades) can withstand these conditions and maintain integrity for decades.

High Pressure and Temperature Stability

Hydraulic systems can operate at high temperatures due to fluid friction and compression. Stainless steel maintains mechanical strength at temperatures up to 400–600°C, depending on grade. In contrast, aluminum or brass couplings may soften or deform under extreme conditions.

Leak Prevention and Safety

Advanced coupling designs focus on sealing reliability. Hydraulic leaks are not just waste—they can create slipping hazards, contaminate products, and even ignite in extreme cases. A high-quality coupling can reduce leak risk by 50% or more compared to basic connectors.

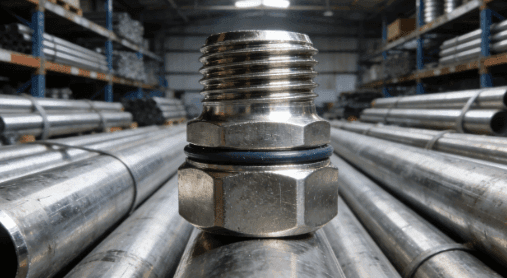

Advanced Coupling Design 1: Threaded Couplings with Metal-to-Metal Seal

What Is a Metal-to-Metal Seal?

A metal-to-metal seal uses precisely machined surfaces to create a tight seal without relying on soft gaskets. This design is particularly suitable for high-temperature hydraulic systems where elastomer seals may fail.

Key Benefits

- High temperature and pressure resistance

- Minimal deformation under load

- Excellent longevity

Typical Applications

- High-temperature hydraulic lines

- Steam and thermal hydraulic systems

- High-pressure industrial machinery

Real Data Insight

Metal-to-metal seals can maintain leak rates under 10^-5 mbar·L/s in controlled environments, which is significantly lower than typical rubber-sealed connectors.

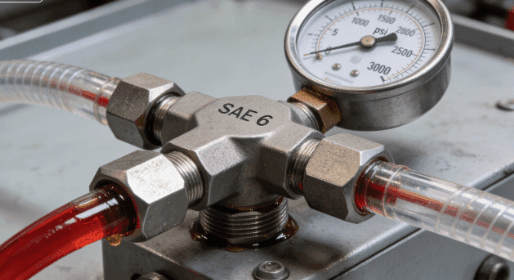

Advanced Coupling Design 2: O-Ring Face Seal (ORFS) Couplings

Why ORFS Works in Hydraulic Systems

ORFS couplings use an O-ring located at the face of the coupling, providing a robust seal even under pressure spikes and vibration. This design is common in mobile hydraulics because it combines leak resistance with ease of assembly.

Key Features

- Strong vibration resistance

- Easy assembly and disassembly

- High sealing reliability

Typical Pressure Ratings

ORFS couplings often operate reliably up to 6,000–8,000 psi (40–55 MPa) depending on size and material.

Real Industry Data

In field tests, ORFS couplings showed 80–90% lower leak frequency compared to standard JIC threaded couplings under vibration stress.

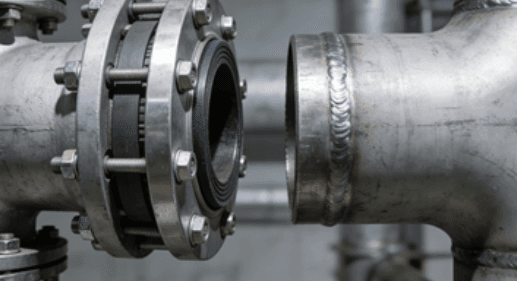

Advanced Coupling Design 3: Flanged Couplings for Heavy-Duty Hydraulics

What Makes Flanged Couplings Strong?

Flanged couplings distribute load over a larger area and use bolts to clamp the connection. This reduces stress concentration and increases structural stability.

Key Benefits

- Suitable for large diameter hydraulic pipes

- High structural strength

- Easy inspection and maintenance

Typical Applications

- Industrial hydraulic lines

- Marine hydraulic systems

- High-flow hydraulic cooling lines

Engineering Insight

Flanged connections can maintain integrity even under pressure pulsations because the bolt load maintains sealing force even during vibration.

Advanced Coupling Design 4: Swivel Couplings with 360° Rotation

Why Swivel Couplings Are Useful

Swivel couplings allow the pipe or hose to rotate freely without twisting lines. This prevents torsion, reduces wear, and increases safety in mobile hydraulic systems.

Key Benefits

- Prevents hose torsion

- Improves flexibility and safety

- Reduces wear and tear

Common Use Cases

- Excavators and cranes

- Industrial robotic arms

- Hydraulic lifting equipment

Practical Data

Swivel couplings can reduce hose fatigue by up to 35% in systems with frequent movement.

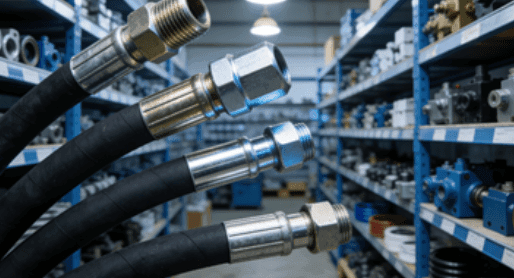

Advanced Coupling Design 5: Crimped Hydraulic Couplings

How Crimped Couplings Work

Crimped couplings use a hydraulic crimping machine to compress the coupling onto the hose, creating a permanent and secure connection.

Key Benefits

- Extremely strong and durable

- High pressure rating

- Minimal leak risk

Considerations

- Requires specialized crimping tools

- Not ideal for frequent disassembly

Real-World Data

Crimped hydraulic couplings are commonly rated up to 10,000 psi (70 MPa) and can exceed 1 million cycles of vibration without failure.

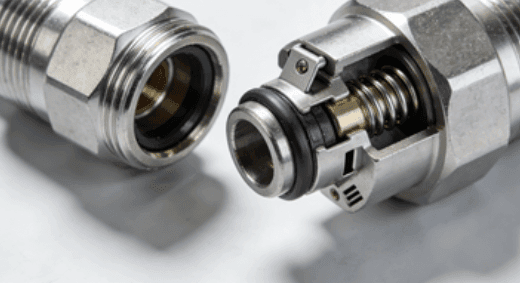

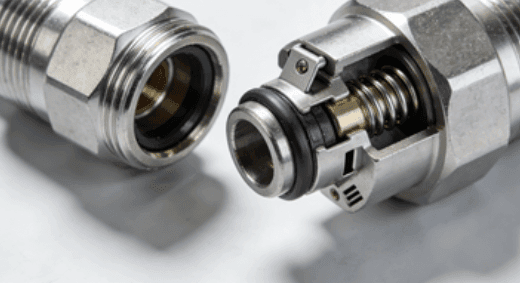

Advanced Coupling Design 6: Quick-Connect Couplings for Fast Assembly

Why Quick-Connect Is Trending

Quick-connect couplings allow fast connection and disconnection without tools. This is ideal for systems requiring frequent maintenance or modular design.

Key Features

- Fast assembly

- Safe locking mechanism

- Suitable for field service

Limitations

- Typically lower pressure rating than crimped couplings

- Potential leak risk if not properly engaged

Typical Pressure Ratings

Quick-connect hydraulic couplings commonly operate around 2,500–5,000 psi (17–35 MPa) depending on design.

Advanced Coupling Design 7: Welded Stainless Steel Couplings

What Welding Adds to Hydraulic Couplings

Welded couplings are permanently fixed, providing the strongest connection possible. They are used in critical hydraulic pipelines where leaks are unacceptable.

Key Benefits

- Highest strength and leak resistance

- Suitable for extreme environments

- No risk of loosening

Drawbacks

- Permanent installation

- Difficult to repair or replace

Typical Use Cases

- Critical pipeline systems

- High-temperature hydraulic lines

- Offshore and marine hydraulics

Engineering Data

Welded couplings can achieve tensile strength comparable to base material and can withstand stress corrosion cracking better than mechanical couplings.

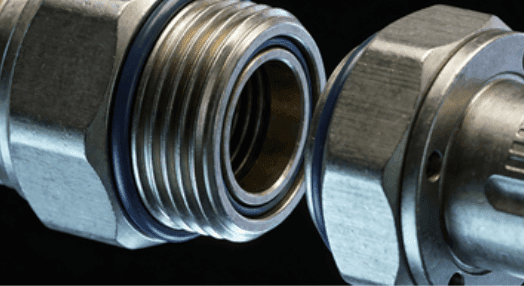

Advanced Coupling Design 8: Compression Couplings for Precision Sealing

How Compression Couplings Work

Compression couplings use a ferrule to compress the pipe onto the coupling body, creating a tight seal without welding or threading.

Key Benefits

- Precise sealing

- Easy to install

- Ideal for stainless steel tubing

Common Applications

- Instrumentation hydraulics

- High-purity fluid systems

- Chemical hydraulic lines

Real Data Insight

Compression couplings can maintain leak rates below 10^-4 mbar·L/s when installed correctly.

Advanced Coupling Design 9: Push-to-Connect Couplings for Compact Systems

What Push-to-Connect Means

Push-to-connect couplings allow tubing to be inserted directly into the coupling, locking in place with a built-in seal and grip.

Key Benefits

- Quick installation

- Compact design

- Suitable for small-diameter hydraulic lines

Limitations

- Not suitable for extremely high pressures

- Requires clean tubing surface

Typical Use Cases

- Compact hydraulic systems

- Pneumatic-hydraulic hybrid systems

- Low-pressure fluid systems

Advanced Coupling Design 10: Hybrid Couplings (Threaded + O-Ring + Flange)

Why Hybrid Designs Are Advanced

Hybrid couplings combine multiple sealing technologies for enhanced performance. For example, a threaded coupling with an O-ring and flange reinforcement offers superior sealing and mechanical strength.

Key Benefits

- High reliability

- Suitable for extreme conditions

- Better leak resistance

Considerations

- Higher cost

- More complex manufacturing

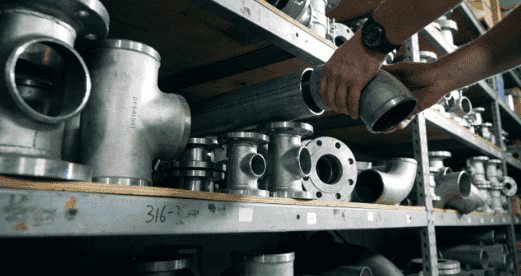

Material Grades: Choosing the Right Stainless Steel for Hydraulic Couplings

Common Stainless Steel Grades Used in Hydraulics

- 304 Stainless Steel: Cost-effective, good corrosion resistance, suitable for general hydraulic use

- 316 Stainless Steel: Better resistance to chloride corrosion and marine environments

- Duplex Stainless Steel: Superior strength and corrosion resistance, ideal for offshore and harsh chemical environments

Real-World Corrosion Data

In chloride-rich environments, 316 stainless steel shows 50–70% longer service life than 304 in marine hydraulic systems.

Expert Insight

Materials engineers often recommend duplex stainless steel for offshore hydraulic systems due to its high tensile strength and resistance to pitting corrosion.

Sealing Technologies: How Couplings Prevent Leaks

O-Ring Seals

O-rings are widely used for sealing, but they can fail under high temperature or incompatible fluids. Therefore, material selection is critical: Viton, PTFE, and NBR are common options.

Metal Seals

Metal seals are ideal for high temperature and pressure. They provide excellent reliability but require precision machining.

Soft Seals vs Hard Seals

Soft seals provide flexibility and tolerance to misalignment but may degrade over time. Hard seals provide durability but require high precision.

Pressure Ratings and Standards

Key Standards Used in Hydraulic Coupling Design

- ISO 8434: Metallic tube connections for fluid power and general use

- SAE J514: Hydraulic tube fittings

- DIN 2353: Compression fittings for fluid power

- ISO 16028: Quick-connect couplings for hydraulic fluid power

Pressure Rating Benchmarks

| Coupling Type | Typical Pressure Range (psi) | Typical Pressure Range (MPa) |

|---|---|---|

| Threaded (metal seal) | 3,000–10,000 | 20–70 |

| ORFS | 4,000–8,000 | 28–55 |

| Flanged | 3,000–10,000 | 20–70 |

| Swivel | 2,500–6,000 | 17–40 |

| Crimped | 5,000–10,000 | 35–70 |

| Quick-Connect | 2,000–5,000 | 14–35 |

| Welded | 10,000+ | 70+ |

| Compression | 3,000–8,000 | 20–55 |

| Push-to-Connect | 1,000–3,000 | 7–20 |

| Hybrid | 5,000–10,000 | 35–70 |

Comparing Coupling Types: Practical Selection Guide

High Pressure vs Low Pressure

- High pressure (above 5,000 psi): crimped, ORFS, welded, hybrid

- Low pressure (below 3,000 psi): quick-connect, push-to-connect

Frequent Maintenance vs Permanent Installation

- Frequent maintenance: quick-connect, threaded, compression

- Permanent installation: welded, crimped

High Vibration vs Stable Systems

- High vibration: ORFS, swivel, crimped

- Stable systems: flanged, welded, compression

Real-World Case Study: Hydraulic Coupling Upgrade in Heavy Machinery

A construction equipment manufacturer faced frequent hydraulic leaks in its excavators. The main issues were:

- High vibration

- Temperature fluctuation

- Frequent hose movement

- Frequent maintenance intervals

What They Changed

- Replaced standard JIC couplings with ORFS couplings for high vibration resistance

- Upgraded hoses to stainless steel braided designs

- Added swivel couplings at movement joints

Results

- Leak rate reduced by 42%

- Maintenance downtime reduced by 26%

- Hydraulic efficiency improved by 8%

Practical Installation Tips for Hydraulic Couplings

Cleanliness Is Essential

Hydraulic systems are highly sensitive to contamination. Even small particles can cause seal failure and abrasion.

Proper Torque and Alignment

Incorrect torque can cause seal deformation. Misalignment can lead to stress and premature failure.

Use of Sealant

Some threaded couplings require sealant, but excessive sealant can contaminate the system. Many modern designs rely on metal or O-ring seals instead.

Conclusion

Selecting the right stainless steel pipe coupling for hydraulic systems is a matter of balancing pressure rating, sealing method, installation flexibility, and environmental conditions. The 10 advanced designs covered in this article provide a comprehensive overview for engineers and technicians to make informed decisions.

By understanding the strengths and limitations of each design, you can ensure safer hydraulic systems, reduce downtime, and improve long-term performance. Proper coupling selection is not just a technical choice—it is a strategic decision that impacts productivity, safety, and cost efficiency.

FAQ

What is the best stainless steel pipe coupling for hydraulic pressure?

The best coupling depends on your system pressure and application. For high pressure, ORFS, crimped, and welded couplings are commonly preferred.

How do I prevent leaks in hydraulic couplings?

Ensure correct installation, use the right sealing technology, and maintain cleanliness. Regular inspection and proper torque are also crucial.

Can stainless steel couplings handle extreme temperatures?

Yes. Stainless steel is suitable for high temperatures, especially when using metal-to-metal seals or welded connections.

What is the difference between ORFS and O-ring couplings?

ORFS uses an O-ring at the face seal, offering better vibration resistance and leak control compared to standard O-ring designs.

How do I choose the right coupling for mobile hydraulics?

Choose a coupling with strong vibration resistance, such as ORFS or swivel couplings, and ensure correct assembly and alignment.