Table of Contents

Introduction

In the intricate world of hydraulic systems, every component plays a crucial role in ensuring efficient and reliable operation. Among these, hydraulic hose fittings stand out as indispensable elements. These components are designed to connect the hydraulic system, facilitating the transmission of power and pressure through hydraulic oil.

A properly attached hydraulic hose fitting ensures the integrity of the entire system, preventing leaks, maintaining optimal pressure, and ultimately contributing to the longevity and performance of hydraulic equipment. Without secure and precise connections, even the most advanced hydraulic systems can suffer from inefficiencies, premature wear, and costly downtime. This guide aims to provide a comprehensive understanding of how to properly attach hydraulic hose fittings, highlighting key considerations, common challenges, and expert solutions to ensure a robust and leak-free hydraulic connection.

Understanding the Importance of Proper Hydraulic Hose Fitting Installation

The functionality and reliability of any hydraulic system heavily depend on the correct installation of its hydraulic hose fittings. Improper attachment can lead to a cascade of problems, from minor inconveniences like oil leakage to severe issues such as system shutdown due to fitting rupture. Hebei Minglai Pipe Fitting Co., Ltd., a professional company specializing in standard and non-standard hydraulic joints and rubber products, emphasizes that their ultimate goal is to ensure customer satisfaction by using the best materials and strictly testing products according to their quality management system. This commitment to quality underscores the critical nature of these components.

Ensuring leak-free performance is paramount, and there are several essential tips for hydraulic connector installation that apply directly to hydraulic hose fittings. These tips often address common pain points encountered in industrial applications. For instance, frequently encountered issues such as leakage after installation, difficulty in disassembling rusted threads, or the risk of rupture in high-pressure systems all point to the necessity of meticulous attention during the selection and attachment process of hydraulic hose fittings. By understanding and implementing best practices, one can significantly enhance system efficiency, reduce maintenance costs, and extend the operational life of hydraulic equipment.

Addressing Common Hydraulic Hose Fitting Leakage Challenges

One of the most persistent issues faced in hydraulic systems is the frequent leakage of hydraulic hose fittings after installation. Such leaks not only lead to significant oil loss and environmental concerns but also compromise the overall efficiency and safety of the system. To completely solve this problem, a multifaceted approach is required. The primary recommendation is to replace the faulty hydraulic hose fitting with a new one. This ensures that any inherent defects or wear in the existing fitting are eliminated. However, simply replacing the fitting is often not enough.

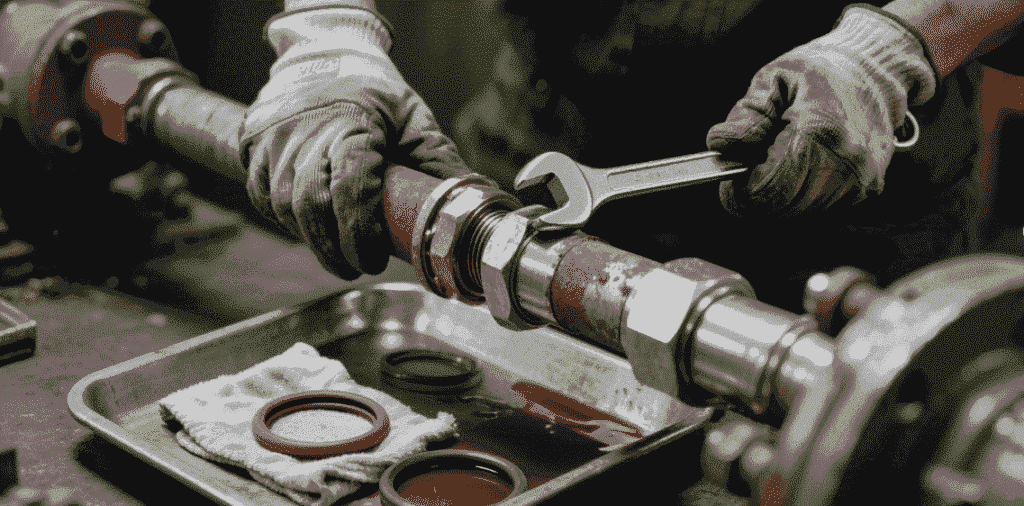

Before installing the new hydraulic hose fitting, it is crucial to thoroughly clean the internal components of the pipe. This involves removing welding slag and oil stains using a suitable solvent such as kerosene or anhydrous ethanol. The objective is to ensure that the sealing surface of the hydraulic hose fitting is entirely free of impurities. Even minute particles can create channels for oil to escape, leading to persistent leaks. This meticulous cleaning step is a cornerstone of achieving a zero-leakage connection and ultra-long durability for industrial-grade hydraulic adapters and fittings. Precision and cleanliness during the attachment process of hydraulic hose fittings are non-negotiable for reliable performance.

Preventing Rust and Enhancing Durability of Hydraulic Hose Fittings

Long-term exposure to various environmental conditions can lead to the rusting of hydraulic hose fitting threads, making disassembly difficult and potentially damaging the components during maintenance. To counteract this, several preventive measures can be employed to enhance the durability and operational lifespan of hydraulic hose fittings.

- Surface Strengthening Treatment for Hydraulic Hose Fittings: One effective strategy is to apply surface strengthening treatments to the threads of the hydraulic hose fittings. This can involve plating with hard chromium, ensuring a thickness of at least 0.02mm. Hard chromium plating provides a robust, corrosion-resistant layer that protects the base metal from oxidation. Another option is to coat the threads with molybdenum disulfide lubricant, which is particularly suitable for working conditions ranging from -20℃ to 200℃. This lubricant not only prevents rust but also reduces friction during assembly and disassembly, further preventing thread damage. For critical applications, selecting hydraulic hose fittings made from stainless steel materials, such as 316L, offers superior corrosion resistance. Such materials have been proven to show no corrosion after salt spray testing for more than 720 hours, demonstrating their resilience in harsh environments.

- Rust Prevention Management for Hydraulic Hose Fittings: Beyond material selection and surface treatments, systematic rust prevention management during storage and operation is vital. When storing hydraulic hose fittings, it is advisable to install a moisture-proof silicone bag within the storage container to absorb any ambient moisture. Additionally, applying rust-proof oil to the contact surfaces of the fittings provides an extra layer of protection against environmental elements. Regular checks of the threads’ cleanliness are also recommended. This can be done by blowing with high-pressure gas to prevent the accumulation of impurities that could trap moisture and initiate corrosion.

- Emergency Response Plan for Rusted Hydraulic Hose Fittings: Despite preventive measures, rusting can sometimes occur. For rusted threads, a prompt emergency response plan can mitigate damage. The threads can be softened using WD-40 penetrant, which helps to loosen the rust. Following this, the threads should be cleaned with a nylon brush to remove the softened rust and debris. In cases of severe corrosion where the threads are significantly damaged, it may be necessary to cut off the damaged section and re-tap the threads. This radical step ensures that new, clean threads can be formed, allowing for a secure and leak-free connection with a new hydraulic hose fitting. Implementing these strategies will significantly extend the life and maintain the functionality of hydraulic hose fittings.

Selecting Robust Hydraulic Hose Fittings for High-Pressure Systems

High-pressure hydraulic systems present unique challenges, with the risk of hydraulic hose fitting rupture posing a significant threat to safety and operational continuity. Choosing the correct hydraulic hose fittings for such demanding environments is crucial to avoid costly shutdowns and potential hazards.

- Accurate Selection Guide for Hydraulic Hose Fittings: The primary guideline for selecting hydraulic hose fittings in high-pressure systems is to ensure that the working pressure of the system does not exceed 80% of the nominal pressure of the fitting. For example, if a system operates at 35MPa, a hydraulic hose fitting rated for 50MPa should be selected. This provides a necessary safety margin. Furthermore, for systems operating under impact conditions, an additional 30% pressure margin should be factored in. High-temperature environments also require careful consideration, as temperature can reduce the strength of materials. The pressure rating of the hydraulic hose fitting should be converted based on a temperature coefficient, typically reducing by 20% for every 100℃ increase in temperature.

- Strengthen Testing Verification for Hydraulic Hose Fittings: Beyond theoretical selection, practical verification is essential. It is recommended to choose hydraulic hose fittings that come with a third-party pressure pulse test report. Such reports demonstrate that the fitting has undergone rigorous testing, for instance, showing no leakage after 100,000 0.5Hz square wave tests. This provides concrete evidence of the fitting’s ability to withstand dynamic and fluctuating pressures. Additionally, incorporating safety relief valves in critical areas of the hydraulic system is a prudent measure. These valves should be set to activate at a value less than 10% of the maximum system pressure, providing an emergency outlet for overpressure and protecting the hydraulic hose fittings from rupture.

- Structural Optimization Suggestions for Hydraulic Hose Fittings: The design and structure of hydraulic hose fittings themselves can be optimized for high-pressure applications. Adopting a double-layer sealing structure, which includes a main seal and a buffer ring, can significantly improve the fitting’s ability to absorb pressure fluctuations and maintain a tight seal. Another structural enhancement involves using thickened pipe wall material. For example, high-pressure hose joints like the SC5S should have an outer diameter of at least 25mm to provide sufficient material strength against high internal pressures. These structural considerations are vital in ensuring that hydraulic hose fittings can reliably perform in the most demanding high-pressure environments.

Achieving Precision in Hydraulic Hose Fitting Thread Alignment

In multi-joint hydraulic systems, misaligned threads during the installation of hydraulic hose fittings can lead to significant hydraulic oil leakage, compromising the entire system’s integrity. Precision in thread alignment is therefore a critical aspect of proper hydraulic hose fitting attachment.

- Standardized Control Measures for Hydraulic Hose Fittings: To mitigate the risk of thread misalignment, establishing a robust thread identification system is highly beneficial. This involves laser printing thread specifications, such as “NPT-1/2-28UNF,” directly onto the hydraulic hose fitting. This clear labeling prevents confusion and ensures that technicians use the correct mating threads. Furthermore, providing a comprehensive size comparison table that includes ISO/ANSI/DIN standard conversion parameters can greatly assist in selecting and matching the appropriate hydraulic hose fittings, especially in systems that may incorporate components from different manufacturers or regions.

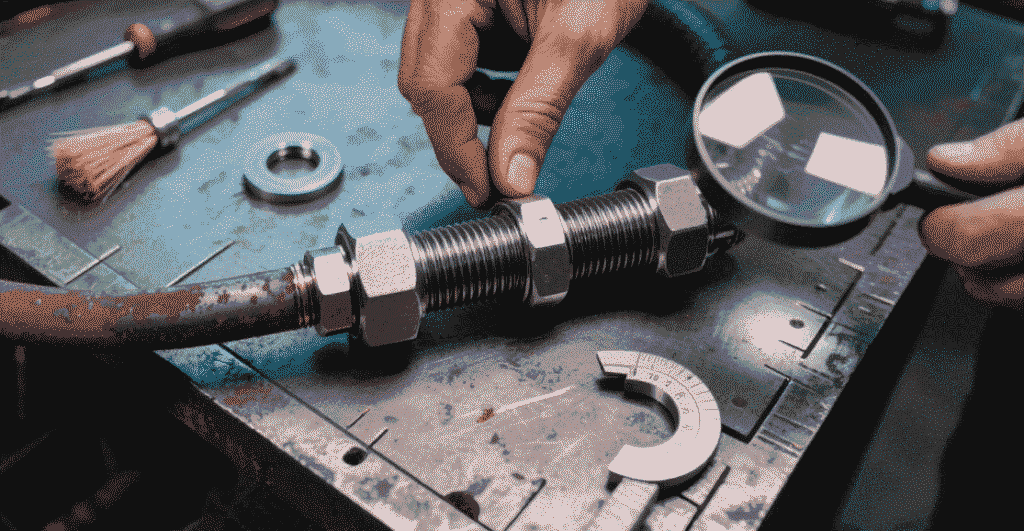

- Precision Detection Equipment for Hydraulic Hose Fittings: Before installation, utilizing precision detection equipment can preemptively identify potential issues with hydraulic hose fittings. An electronic thread gauge, with an accuracy of ±0.01mm, can be used to detect the tooth profile angle (either 60° or 55°) and ensure it matches the specified standard. Additionally, the ovality of the tube body should be carefully checked, ideally being ≤0.05mm. It is recommended to submit samples for retesting before procurement to ensure that all hydraulic hose fittings meet these stringent dimensional tolerances, thus guaranteeing proper thread engagement.

- Professional Installation Guidance for Hydraulic Hose Fittings: Even with correctly manufactured hydraulic hose fittings, improper installation can still lead to thread misalignment. Adopting a standardized torque step method is crucial. This method involves applying torque in stages: an initial torque of 50%, followed by a compound torque of 100%, and finally a tightening torque of 120%. This gradual tightening process allows the threads to seat properly without being forced, reducing the risk of cross-threading or stripping. For accurate and consistent torque application, it is highly recommended to use a hydraulic torque wrench, which typically offers an accuracy of ±3%, in conjunction with a fixed torque socket. Professional installation guidance and the use of specialized tools are indispensable for achieving precise and leak-free attachment of hydraulic hose fittings.

Here is a summary of common hydraulic hose fitting challenges and their solutions:

| Challenge Type | Specific Issue | Recommended Solutions for Hydraulic Hose Fittings |

| Leakage After Installation | Frequent hydraulic oil leakage from hydraulic hose fittings. | Replace the hydraulic hose fitting with a new one; thoroughly clean welding slag and oil stains from the pipe interior with kerosene or anhydrous ethanol to ensure sealing surface is impurity-free. |

| Difficulty in Disassembly Due to Rusting | Rusted threads of hydraulic hose fittings after long-term use. | Surface Strengthening: Plate with hard chromium (≥0.02mm) or coat with molybdenum disulfide lubricant (-20~200℃). Use 316L stainless steel for key parts (no corrosion after ≥720h salt spray test). Rust Prevention: Install moisture-proof silicone bag, apply rust-proof oil, regularly check thread cleanliness. Emergency: Use WD-40, nylon brush, or re-tap. |

| Rupture in High-Pressure Systems | Risk of hydraulic hose fitting rupture leading to system shutdown. | Selection: Working pressure ≤ 80% nominal pressure (e.g., 50MPa for 35MPa system), add 30% margin for impact, convert pressure for high-temperature environments. Testing: Provide third-party pressure pulse test reports (e.g., no leakage after 100,000 0.5Hz tests), add safety relief valves (<10% max system pressure). Structure: Double-layer sealing, thickened pipe wall (SC5S outer diameter ≥ 25mm). |

| Leakage Due to Thread Misalignment | Hydraulic oil leakage caused by misaligned threads during multi-joint system installation. | Standardization: Establish thread identification system (laser print “NPT-1/2-28UNF”), provide size comparison table (ISO/ANSI/DIN). Detection: Use electronic thread gauge (±0.01mm) for tooth profile angle (60° or 55°), check tube body ovality (≤0.05mm). Installation: Adopt torque step method (50%→100%→120%), use hydraulic torque wrench (±3%). |

Why Choose Quality Hydraulic Hose Fittings?

Choosing high-quality hydraulic hose fittings is a decision that impacts the overall performance, safety, and operational costs of hydraulic systems. Hebei Minglai Pipe Fittings Co., Ltd. is described as a professional connector manufacturer specializing in industrial-grade hydraulic adapters, promising zero leakage connection and ultra-long durability. Their commitment stems from a robust approach to production and service that prioritizes customer needs and product excellence.

Advanced Manufacturing and Quality Control for Hydraulic Hose Fittings

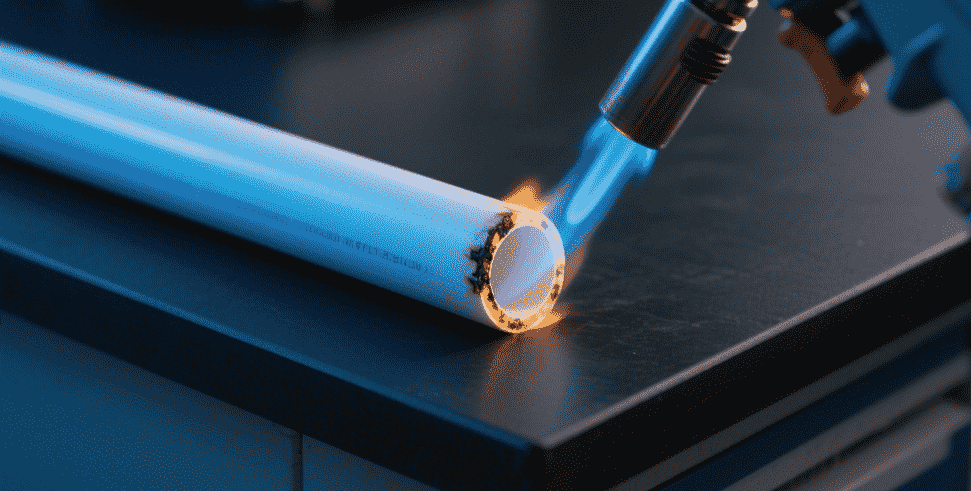

The foundation of reliable hydraulic hose fittings lies in advanced manufacturing processes and stringent quality control. Hebei Minglai Pipe Fittings Co., Ltd. prides itself on its “Smart Manufacturing” approach, defining a closed loop from production to mass production, driven by technology and innovation. They employ advanced processes such as precision forging and laser welding, which are critical in ensuring the accuracy and durability of hydraulic hose fittings. The company’s professional and complete workflow, along with direct supply from source manufacturers, streamlines the production process and contributes to consistent product quality.

Quality control is paramount, with production strictly adhering to international standards such as GB/T, ASME, and DIN. This rigorous adherence ensures that every hydraulic hose fitting meets specific design and performance criteria, offering reliability and consistency. Furthermore, their products have passed several international certifications, including IP68 waterproof, CE, UL, and ROHS, signifying their compliance with global safety and environmental standards. This comprehensive approach to craftsmanship and quality control ensures that the hydraulic hose fittings can withstand the demanding conditions of various industrial applications.

Tailored Solutions and Customer-Centric Approach for Hydraulic Hose Fittings

Understanding that different industries and applications have unique requirements, the company emphasizes its ability to provide tailored hydraulic hose fittings. With a professional design team possessing independent development capabilities, they can offer customized solutions that flexibly address diverse needs. This includes dedicated support for custom stainless steel hydraulic components, leveraging strong engineering capabilities, precision manufacturing, and rigorous quality inspection systems.

Their services extend beyond just product design and manufacturing; they encompass full lifecycle technical support and rapid service response. This holistic approach helps clients improve system efficiency, reduce maintenance costs, and shorten project cycles. The company’s R&D capability specifically supports customization to meet the needs of customers across various industries, including OEM/ODM services.

Testimonials from customers, such as Harrison Atkinson, CEO of Lokamart, highlight how their hydraulic hose fittings have dispelled concerns about leakage, exceeding expectations in quality. Bethany Rogers, Founder of Makko, expressed being truly impressed by the connectors, while Samuel Wood, also from Makko, lauded the delivery speed for urgent needs. This customer feedback underscores their commitment to using the best materials and providing effective solutions for hydraulic hose fittings, building trust with their clientele.

Conclusion

Properly attaching hydraulic hose fittings is an art and a science, demanding attention to detail, adherence to standards, and the selection of quality components. The reliability of hydraulic systems, from power transmission to pressure maintenance, hinges on the integrity of these connections. By understanding the common challenges—such as leakage, rust, and rupture in high-pressure environments—and implementing the expert solutions discussed, operators can significantly enhance system performance and longevity. From meticulous cleaning and surface treatments to precise torque application and robust material selection, each step contributes to creating a zero-leakage, ultra-durable hydraulic connection.

Ultimately, investing in high-quality hydraulic hose fittings and following best practices for their attachment is not just about preventing problems; it’s about optimizing efficiency, reducing operational costs, and ensuring the safety and continuous operation of vital hydraulic equipment.

FAQ

Q1: How can frequent leakage of hydraulic hose fittings after installation be completely solved?

A1: To resolve frequent leakage, you should replace the hydraulic hose fitting with a new one. Before installation, thoroughly clean any welding slag and oil stains from inside the pipe using kerosene or anhydrous ethanol, ensuring the sealing surface is entirely free of impurities.

Q2: How can the difficulty of disassembly caused by rusting of hydraulic hose fitting threads after long-term use be prevented?

A2: Prevention involves several strategies. You can apply surface strengthening treatments like plating with hard chromium (thickness ≥ 0.02mm) or coating with molybdenum disulfide lubricant (suitable for -20~200℃ conditions) at the thread. Alternatively, key parts can be made from stainless steel (e.g., 316L), which has shown no corrosion after salt spray testing for over 720 hours. For rust prevention management, install a moisture-proof silicone bag during storage and apply rust-proof oil to contact surfaces. Regularly check thread cleanliness by blowing with high-pressure gas to prevent impurity accumulation. In emergencies, rusted threads can be softened with WD-40 penetrant and cleaned with a nylon brush; severe corrosion may require cutting off the damaged section and re-tapping.

Q3: How should hydraulic hose fittings be chosen to avoid the risk of shutdown caused by joint rupture in a high-pressure system?

A3: For accurate selection, ensure the working pressure is ≤ 80% of the hydraulic hose fitting’s nominal pressure (e.g., a 50MPa fitting for a 35MPa system). Add an additional 30% margin for impact conditions, and convert pressure for high-temperature environments based on the temperature coefficient (reduced by 20% for every 100℃).

Strengthen testing verification by requesting a third-party pressure pulse test report (e.g., no leakage after 100,000 0.5Hz square wave tests). Add safety relief valves to critical areas, setting their value to less than 10% of the maximum system pressure. Structural optimization suggestions include adopting a double-layer sealing structure (main seal + buffer ring) to absorb pressure fluctuations and using thickened pipe wall material (e.g., high-pressure hose joint SC5S outer diameter ≥ 25mm).

Q4: How can hydraulic oil leakage caused by thread misalignment during the installation of multi-joint systems be avoided?

A4: To prevent leakage from thread misalignment, implement standardized control measures: establish a thread identification system (laser print “NPT-1/2-28UNF” on the hydraulic hose fitting) and provide a size comparison table including ISO/ANSI/DIN standard conversion parameters. Utilize precision detection equipment such as an electronic thread gauge (accuracy ± 0.01mm) to detect the tooth profile angle (60° or 55°) and ensure the tube body ovality is ≤ 0.05mm (submitting samples for retesting before procurement is recommended). For professional installation guidance, adopt the torque step method (initial torque 50% → compound torque 100% → final torque 120%) and use a hydraulic torque wrench (with an accuracy of ± 3%) in conjunction with a fixed torque socket.