Key Takeaways (Must-Read List)

- Learn the exact meaning of SAE 8 hydraulic fitting and why it matters

- Discover how to match fittings with hoses, ports, and adapters

- Understand pressure limits, material selection, and sealing principles

- Compare SAE 8 vs JIC vs ORFS vs BSP vs NPT

- Find real-world compatibility issues and prevention tips

- Access industry data, standards references, and expert quotes

- Use the table of quick reference dimensions and pressure ratings

- Read a practical FAQ section based on current user search habits

Table of Contents

Introduction

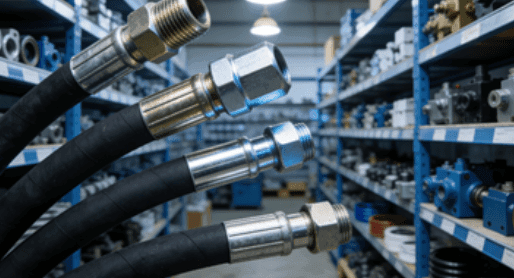

Hydraulic systems are the backbone of modern machinery, from construction equipment to industrial automation. In many cases, the difference between a reliable system and frequent failures comes down to one small component: the fitting. A wrong SAE 8 hydraulic fitting can cause leakage, system pressure loss, and even catastrophic failure.

According to a hydraulic engineering study published by the Hydraulic Institute, improper fitting selection is one of the top causes of hydraulic failures in industrial systems. In other words, compatibility is not just about fitting sizes—it is a matter of system reliability, operator safety, and cost efficiency.

This guide helps you understand the full compatibility picture of SAE 8 fittings, so you can make the right decision every time.

What Does SAE 8 Hydraulic Fitting Mean?

SAE stands for the Society of Automotive Engineers, and SAE 8 refers to a standard fitting size often used in hydraulic systems. In practical terms, SAE 8 commonly corresponds to 1/2-inch hydraulic lines in many systems, but the key is the thread type and sealing method, not just diameter.

Why SAE 8 Is Common in Hydraulic Systems

- High pressure capability

- Wide industry adoption

- Availability of multiple sealing options

- Standardized dimensions and performance

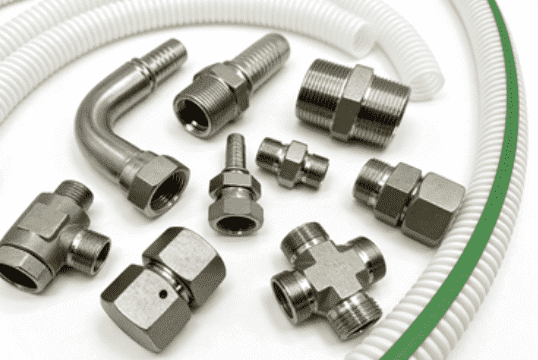

SAE 8 Fitting Types and Their Sealing Principles

When working with hydraulic systems, selecting the right SAE 8 hydraulic fitting is not just about matching thread size. The sealing principle and connection type directly affect system performance, leakage risk, and service life. Below, we break down the most common SAE 8 hydraulic fitting types and explain how they seal, what they are best for, and where they are commonly used.

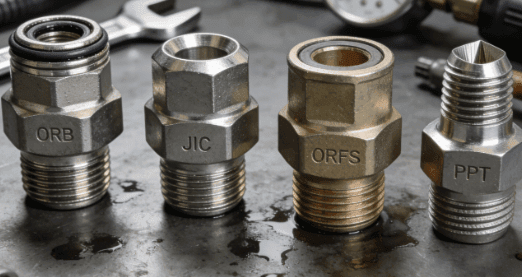

SAE 8 ORB (O-Ring Boss)

Sealing Principle

SAE 8 hydraulic fitting ORB uses an O-ring located in a recessed port. When the fitting is tightened, the O-ring compresses and forms a tight seal. This design is widely used because it offers a reliable and leak-resistant connection.

Why It Works Well

- The combination of metal-to-metal contact and O-ring sealing makes it robust.

- The O-ring provides a secondary seal that compensates for minor surface imperfections.

- It is especially useful in systems where vibration is present but not extreme.

Typical Applications

- Industrial hydraulic systems

- Mobile machinery such as forklifts and loaders

- Factory automation equipment

Common Mistakes

- Using an SAE 8 hydraulic fitting ORB without the correct O-ring size or material can lead to leaks.

- Assuming ORB fittings are compatible with other SAE types; they are not interchangeable.

SAE 8 JIC (37° Flare)

Sealing Principle

SAE 8 hydraulic fitting JIC uses a 37° flare design. The seal is formed by metal-to-metal contact between the flare surfaces when tightened. This design can withstand high pressure and vibration.

Why It Works Well

- The 37° flare creates a strong mechanical seal that is reliable under high pressure.

- The design is popular because it is widely standardized and easy to source.

- It is suitable for applications where the system experiences frequent movement or vibration.

Typical Applications

- Hydraulic cylinder connections

- High-pressure pump lines

- Construction and agricultural machinery

Common Mistakes

- Repeated assembly and disassembly can wear the flare surfaces, leading to leakage.

- Using a JIC SAE 8 hydraulic fitting for applications that require an O-ring seal can reduce reliability.

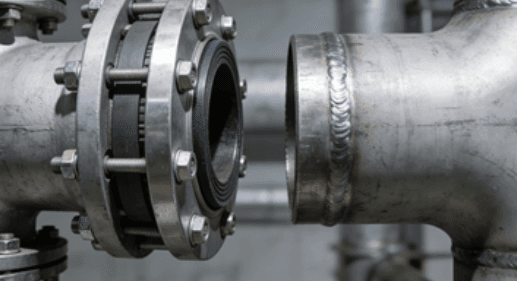

SAE 8 ORFS (O-Ring Face Seal)

Sealing Principle

SAE 8 hydraulic fitting ORFS uses a face seal with an O-ring installed on the face of the fitting. When tightened, the O-ring compresses between the fitting face and the port surface to create a leak-proof seal.

Why It Works Well

- The face seal design is highly reliable, especially for high-pressure systems.

- ORFS fittings are excellent for applications that require frequent maintenance because the seal remains stable after multiple assemblies.

- It provides superior resistance to vibration compared to JIC and ORB.

Typical Applications

- Mining equipment hydraulic systems

- Marine hydraulic systems

- High-performance industrial systems

Common Mistakes

- Using the wrong O-ring material for the fluid type (e.g., using NBR for aggressive chemicals) can cause early failure.

- Installing an ORFS SAE 8 hydraulic fitting without proper torque can cause seal deformation.

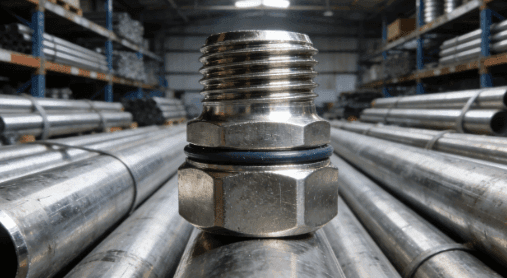

SAE 8 NPT (Tapered Pipe Thread)

Sealing Principle

SAE 8 hydraulic fitting NPT uses tapered pipe threads to seal. The seal is achieved by thread compression, often with thread tape or sealant.

Why It Is Less Ideal for Hydraulic Systems

- NPT relies on thread compression, not a dedicated sealing surface.

- It can be prone to leaks under high pressure or vibration.

- It requires careful installation and correct sealing materials.

Typical Applications

- Low-pressure fluid systems

- General plumbing and piping

- Non-critical hydraulic lines

Common Mistakes

- Using NPT fittings in high-pressure hydraulic systems without proper sealing and torque can cause leaks.

- Assuming NPT is interchangeable with ORB, JIC, or ORFS; it is not.

Quick Comparison Table: SAE 8 Hydraulic Fitting Types

| Fitting Type | Sealing Method | Best Use | Pros | Cons |

|---|---|---|---|---|

| ORB | O-ring in boss | General hydraulic systems | Reliable, easy to install | O-ring material sensitive |

| JIC | 37° flare | High pressure, vibration | Strong metal seal | Wear after repeated use |

| ORFS | Face O-ring | High-pressure, high reliability | Excellent leak resistance | Higher cost |

| NPT | Tapered thread | Low-pressure piping | Low cost, widely available | Not ideal for high pressure |

How to Confirm SAE 8 Hydraulic Fitting Compatibility

Check the Thread Type

Even if the thread size looks similar, thread type may differ. For example, SAE 8 ORB and SAE 8 JIC may have similar diameter but different sealing mechanisms.

Check the Sealing Method

- O-ring seal

- Flare seal

- Face seal

- Tapered thread seal

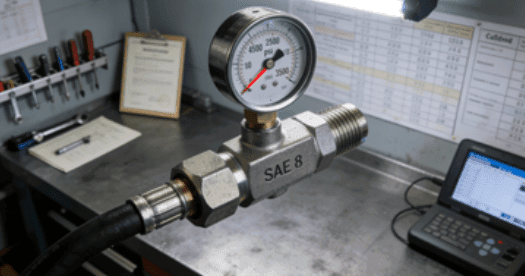

Confirm Pressure Rating

Each fitting type has different pressure capabilities. For example, ORFS fittings typically handle higher pressures than ORB or JIC.

According to industry standards, JIC fittings are commonly rated for up to 6000 psi in 1/2″ size, while ORFS can reach up to 7000 psi in similar sizes depending on material and design.

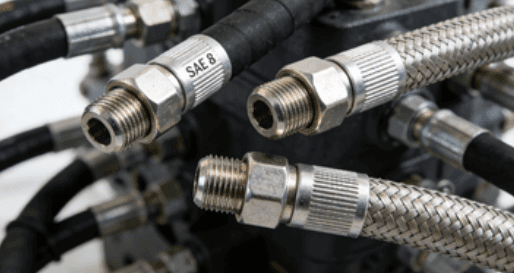

How to Match SAE 8 Fittings with Hoses and Ports

Hose End Type Must Match

If your hose end is ORB, the port must also be ORB. Mixing different sealing types can cause leakage.

Port Type Must Match

Some hydraulic pumps and valves use ORFS ports, while others use ORB. Confirm before purchase.

Adapter Use

Adapters can bridge mismatched standards, but must be selected carefully based on pressure rating and thread compatibility.

SAE 8 vs Other Standards: Practical Comparison

SAE 8 vs JIC

- JIC uses a 37° flare seal

- ORB uses O-ring seal

- JIC is better for high pressure and vibration

- ORB is easier to assemble and more leak-resistant in static applications

SAE 8 vs ORFS

- ORFS offers a face seal with an O-ring

- ORFS is more resistant to high pressure and vibration

- ORFS is typically more expensive but more reliable for heavy-duty systems

SAE 8 vs BSP

BSP has different thread angles and sealing types, making it generally incompatible with SAE without adapters.

SAE 8 vs NPT

NPT is tapered and seals by thread compression. It is not recommended for hydraulic systems where vibration and high pressure are present.

Material Selection for SAE 8 Hydraulic Fittings

Steel

High strength, suitable for high pressure and heavy-duty applications.

Stainless Steel

Best for corrosion resistance, such as marine, chemical, and outdoor applications.

Brass

Suitable for low-pressure and non-critical systems.

Aluminum

Lightweight but not recommended for high-pressure hydraulic systems.

Expert Insight: Why SAE 8 Fitting Choice Matters

According to a senior hydraulic engineer at a leading industrial manufacturer, “Fittings are often overlooked, but they directly impact system reliability. The wrong seal type causes micro leaks that grow over time, leading to major failure.”

This view aligns with many industrial maintenance reports: the majority of hydraulic leaks are caused by improper fitting selection or poor assembly.

Compatibility Table: Quick Reference for SAE 8 Fittings

| Standard | Seal Type | Thread Type | Typical Pressure | Best Use Case | Compatibility Notes |

|---|---|---|---|---|---|

| SAE 8 ORB | O-ring | Straight | Up to 6000 psi | General hydraulic systems | Requires ORB port |

| SAE 8 JIC | 37° flare | Straight | Up to 6000 psi | High pressure systems | Not compatible with ORB |

| SAE 8 ORFS | Face seal + O-ring | Straight | Up to 7000 psi | Heavy-duty systems | High reliability |

| BSP | Tapered | Taper | Varies | Industrial plumbing | Not compatible without adapter |

| NPT | Tapered | Taper | Varies | General plumbing | Not recommended for hydraulic systems |

Common Compatibility Problems and How to Avoid Them

Problem: Thread Size Looks Right but Seal Fails

Cause: Different sealing style

Solution: Confirm the seal type (O-ring, flare, face seal) and choose the correct fitting.

Problem: Leakage After Tightening

Cause: O-ring damage or wrong thread type

Solution: Replace O-ring and verify thread compatibility.

Problem: Pressure Loss or Burst

Cause: Fitting rated below system pressure

Solution: Choose a higher rated fitting like ORFS or JIC.

Real-World Application Scenarios

Construction Equipment

Construction machinery often uses SAE 8 fittings due to their durability and pressure capacity. JIC fittings are especially common in mobile hydraulics.

Industrial Manufacturing

In factories, ORFS fittings are preferred for high-pressure systems because of their reliable face seal.

Marine and Chemical Industry

Stainless steel ORB fittings are used for corrosion resistance.

Compatibility Checklist for Buyers and Engineers

Before Buying

- Confirm the fitting standard

- Confirm the sealing method

- Confirm the pressure rating

- Confirm the hose end type

- Confirm the port type

Before Installation

- Use correct torque

- Inspect O-rings for damage

- Ensure threads are clean

- Use correct sealing material if needed

Conclusion

Choosing the right SAE 8 hydraulic fitting is more than matching thread size. It requires understanding the sealing method, pressure rating, material, and system requirements. When you follow the compatibility tips in this guide, you can reduce leaks, improve system reliability, and save cost in the long run.

FAQ

What is the difference between SAE 8 ORB and SAE 8 JIC?

ORB uses an O-ring seal, while JIC uses a 37° flare. They are not interchangeable without adapters.

How do I know if my fitting is SAE 8?

Check the thread type and sealing method. SAE 8 typically corresponds to a 1/2-inch line size, but confirm using a thread gauge.

Can I use an SAE 8 fitting with NPT?

Not directly. NPT is tapered and seals by thread compression, which is not suitable for high-pressure hydraulic systems.

What happens if I mix ORB and JIC fittings?

Mixing may cause leakage or system failure due to incompatible sealing mechanisms.

Are SAE 8 fittings good for high pressure?

Yes, especially JIC and ORFS types. Always verify the pressure rating for your system.

Can SAE 8 Hydraulic Fitting be reused?

Yes, but only if the sealing surfaces and threads are in good condition. Reusing SAE 8 hydraulic fitting repeatedly may wear the sealing area, especially for JIC flare fittings, leading to leaks.

How do I choose the correct SAE 8 Hydraulic Fitting for my hydraulic hose?

Choose based on hose size, pressure rating, and connection type. If your hose is rated for high pressure, prefer SAE 8 hydraulic fitting types like JIC or ORFS.

What is the difference between SAE 8 Hydraulic Fitting ORB and ORFS?

ORB uses an O-ring inside a boss, while ORFS uses a face seal with an O-ring on the fitting face. Both are leak-resistant, but SAE 8 hydraulic fitting ORFS offers better vibration resistance.

Is SAE 8 Hydraulic Fitting compatible with metric fittings?

Generally no. SAE and metric threads have different dimensions and angles. Mixing SAE 8 hydraulic fitting with metric fittings requires adapters.