Key Takeaways

- Flange pipe connector provides superior maintenance convenience and reusability compared to welded joints

- Flanges support high-pressure and high-temperature applications with clear safety margins

- Welded joints have advantages in cost and compactness, but are less flexible for repair and modification

- Flange systems allow standardization and interchangeability across international piping standards

- For modern industrial plants, flanges offer better inspection, leakage prevention, and compliance

Table of Contents

Introduction

In modern industrial piping, the debate between flange pipe connector vs welded joint has existed for decades.

But in the past 10 years, flange systems have grown rapidly in popularity, especially in industries like oil & gas, chemical, power plants, water treatment, and food processing.

The reason is simple: modern factories no longer value only low cost; they demand reliability, safety, ease of maintenance, and compliance.

That is exactly where flange pipe connectors outperform welded joints.

What Is a Flange Pipe Connector?

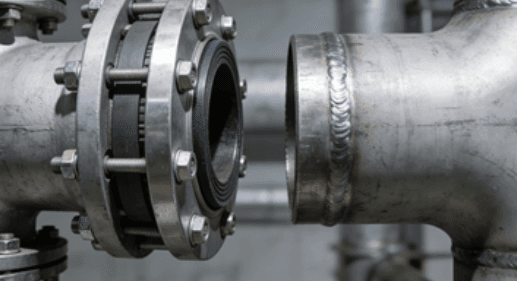

Flange Definition

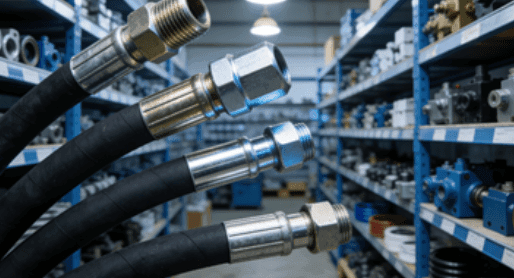

A flange pipe connector is a mechanical joining method that connects pipes using flanges (flat rings) bolted together, usually with a gasket between them to seal the joint.

Flange System Components

- Flange (weld neck, slip-on, blind, socket weld, lap joint, etc.)

- Gasket (PTFE, graphite, rubber, metal spiral wound, etc.)

- Bolts & Nuts

- Alignment and Support structures

Why Flange Is Not Just a “Connector”

Flanges represent an integrated piping strategy:

- Standardization

- Inspection

- Maintenance

- Safety

- Flexibility

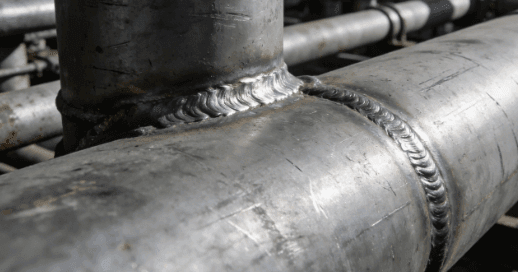

What Is a Welded Joint?

Welded Joint Definition

A welded joint connects pipes by melting and fusing the pipe materials, creating a permanent joint.

Welded Joint Types

- Butt weld

- Socket weld

- Fillet weld

- Lap weld

Welded Joint Characteristics

- Strong and compact

- Permanent (hard to modify)

- Requires high-skilled welders and strict QA

Key Comparison: Flange Pipe Connector vs Welded Joint

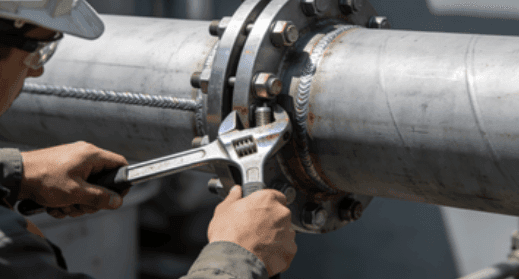

Installation & Maintenance

Flange Pipe Connector

- Quick assembly and disassembly

- Easy to replace gaskets and pipes

- Suitable for frequent maintenance

Welded Joint

- Permanent and difficult to disassemble

- Repair requires cutting, re-welding, and testing

- Maintenance downtime is longer

Why this matters:

In industrial plants, downtime is the most expensive cost. Flanges reduce downtime dramatically.

Cost Analysis

Welded Joint

- Lower initial cost (no bolts, gaskets, flange parts)

- But higher long-term cost due to maintenance and rework

Flange Pipe Connector

- Higher initial cost

- Lower lifecycle cost

Many industry experts estimate that maintenance and replacement costs for welded systems can be 20%–40% higher than flange systems over 10 years.

Pressure & Temperature Capability

Flange

- Suitable for high-pressure pipelines

- Meets international standards (ANSI/ASME, DIN, JIS)

- Can be used in high temperature and cryogenic conditions

Weld

- Also high strength

- But depends heavily on weld quality and material

Conclusion: Flanges provide more predictable performance under variable conditions.

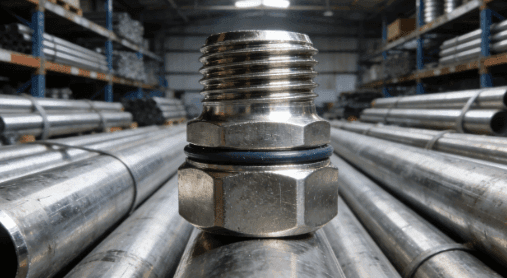

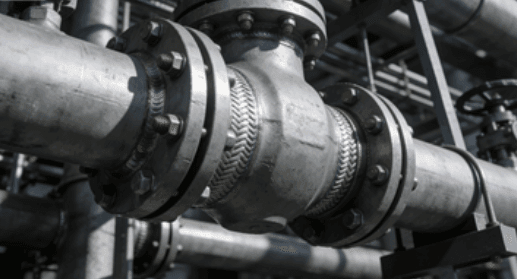

The Biggest Advantage: Flange Is Modular & Standardized

Standardization

Flanges are manufactured to standardized specifications:

- ANSI/ASME B16.5 (most common)

- DIN (Europe)

- JIS (Japan)

- GB (China)

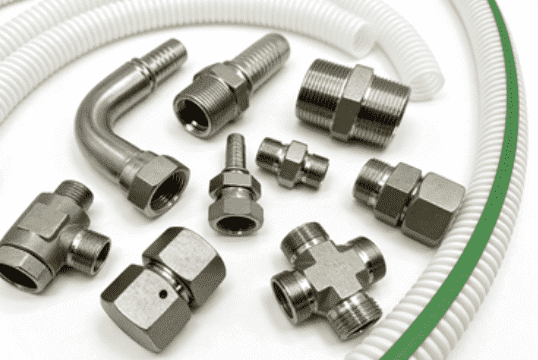

Modular System

A flange system allows modular upgrades:

- Change pipe material without re-welding

- Upgrade valves or instruments quickly

- Add branches or bypass lines easily

This modularity is a major reason why modern plants prefer flanges.

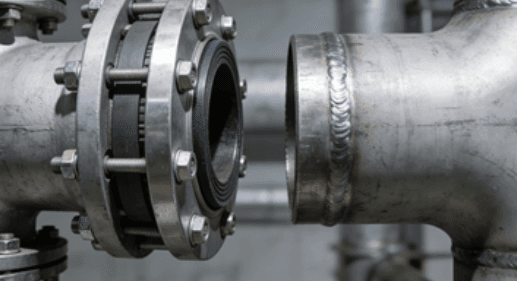

Flange vs Weld: Which Is Safer?

Leakage Risk

- Welded joints leak mainly due to crack formation and weld defects

- Flange leaks are easier to detect and fix (replace gasket, tighten bolts)

Inspection

- Flanges can be inspected visually and with non-destructive testing

- Welded joints require advanced NDT methods (X-ray, ultrasonic) and often need shutdown

Expert view:

Industry safety consultants often recommend flange systems for high-risk applications, because flange joints allow routine inspection and faster response to leakage.

When Welded Joints Are Better

Even though flange has many advantages, welded joints still have real advantages in certain scenarios:

Space Constraints

- Welded joints are compact

- Suitable for tight installations

Low-cost, Long-term Fixed Pipelines

- For pipelines that rarely need maintenance, welding can be cost-effective

High-purity or High-purity Systems

- In some chemical and pharmaceutical systems, welded joints reduce risk of contamination

Flange Pipe Connector: The Best Choice for High Reliability

Flanges are increasingly used in critical industries due to:

- High reliability

- Easy maintenance

- Clear compliance with standards

- Low lifecycle cost

- Flexible system expansion

Practical Data Comparison Table (Flange vs Weld)

| Comparison Category | Flange Pipe Connector | Welded Joint |

|---|---|---|

| Installation Speed | Faster (bolted) | Slower (welding + testing) |

| Maintenance | Easy (disassembly) | Difficult (cut + re-weld) |

| Initial Cost | Higher | Lower |

| Lifecycle Cost | Lower | Higher |

| Leakage Risk | Lower (gasket-based, visible) | Higher (weld defects) |

| Modularity | High | Low |

| Inspection | Easy | Hard |

| Pressure & Temperature | Standardized | Dependent on weld quality |

| Flexibility | High | Low |

| Best for | Industrial plants, valves, maintenance-heavy systems | Fixed pipelines, compact spaces |

Procurement Buyer Guide: How to Choose the Right Flange System

As a procurement manager, your goal is to balance cost, reliability, and compliance.

Check Material Standards

- Carbon steel (A105, ASTM A350 LF2)

- Stainless steel (304, 316, 316L)

- Alloy steel (P91, P22)

Pressure Rating

- Class 150, 300, 600, 900, 1500, 2500

- Choose based on system pressure and temperature

Gasket Selection

- PTFE for chemical

- Graphite for high temperature

- Spiral wound for high pressure

Bolt Material

- Carbon steel (galvanized)

- Stainless steel

- Duplex for corrosive environments

Expert Opinions: Why Flanges Are Preferred

Industry authorities from piping engineering associations and major plant operators often emphasize:

- “Flange systems offer predictable maintenance schedules.”

- “The ability to replace components without shutdown is a game-changer.”

- “Flanges enable standardized procurement and global sourcing.”

This is why major plants are transitioning to flange systems for all key pipeline segments.

Summary: Why Buyers Are Choosing Flange Pipe Connectors

If you are a buyer or procurement manager, your decision should focus on:

- Lifecycle cost

- Safety and compliance

- Maintenance convenience

- System flexibility and scalability

In almost all modern industrial plants, flange pipe connectors provide the best balance of performance and cost, especially in systems requiring frequent inspection, maintenance, and upgrades.

FAQ

Q1: Are flanges more expensive than welding?

Yes, the initial cost is higher, but the total lifecycle cost is usually lower due to easier maintenance and reduced downtime.

Q2: Can flanges handle high pressure?

Yes. Flanges are standardized for high pressure and are widely used in high-pressure systems like oil & gas.

Q3: Which is better for corrosion resistance?

Flanges and welded joints can both be corrosion resistant depending on material and coating. However, flanges allow easier replacement if corrosion occurs.

Q4: Are flange joints leak-proof?

With proper gasket and torque control, flange joints can be highly reliable and leak-resistant.

Q5: What is the best application for welded joints?

Welded joints are best for fixed, compact pipelines where maintenance is rare and space is limited.