Description

Metric Male 24° Cone / BSP 60° Cone Seal – Dual Standard Hydraulic Transition Fitting

Product Overview

The Metric Male 24° Cone / BSP 60° Cone Seal is a specialized hydraulic transition fitting designed to bridge Metric and British Standard Pipe (BSP) thread systems. This unique adapter combines DIN 24° cone sealing (ISO 8434-1) with BSP 60° taper thread sealing, making it an essential component for international hydraulic systems requiring cross-standard compatibility.

Key differentiators from previous products:

- Dual-standard design: Seamlessly connects Metric (M12×1.5 to M52×2) and BSP (G1/8″ to G1-1/2″) threads

- No O-ring required: Relies on precision metal-to-metal cone sealing for both interfaces

- Higher pressure rating: Optimized design withstands up to 50 MPa (7250 psi)

Technical Specifications & Key Parameters

1. Technical Specification

| PART NO. | THREAD | D1 TUBE O.D. | DIMENSIONS | |||||||

| BODY | ASSEMBLY | E | F | B | l1 | L1 | L | S1 | S2 | |

| 1CB-12-02Z | 1CB-12-02RNW | M12X1.5 | G1/8″X28 | 6 | 10 | 8 | 23 | 24 | 14 | 14 |

| 1CB-12-04Z | 1CB-12-04RNW | M12X1.5 | G1/4″X19 | 6 | 12 | 9 | 24 | 28 | 19 | 14 |

| 1CB-14-02Z | 1CB-14-02RNW | M14X1.5 | G1/8″X28 | 8 | 10 | 8 | 23 | 25 | 14 | 17 |

| 1CB-14-04Z | 1CB-14-04RNW | M14X1.5 | G1/4″X19 | 8 | 12 | 9 | 25 | 28 | 19 | 17 |

| 1CB-14-06Z | 1CB-14-06RNW | M14X1.5 | G3/8″X19 | 8 | 13.5 | 9 | 24 | 28.5 | 22 | 17 |

| 1CB-16-04Z | 1CB-16-04RNW | M16X1.5 | G1/4″X19 | 10 | 12 | 10 | 25 | 28 | 19 | 19 |

| 1CB-16-06Z | 1CB-16-06RNW | M16X1.5 | G3/8″X19 | 10 | 13.5 | 12.5 | 25 | 33 | 22 | 19 |

| 1CB-16-08Z | 1CB-16-08RNW | M16X1.5 | G1/2″X14 | 10 | 16 | 11 | 26 | 32 | 27 | 19 |

| 1CB-18-04Z | 1CB-18-04RNW | M18X1.5 | G1/4″X19 | 12 | 12 | 10 | 25 | 29 | 19 | 22 |

| 1CB-18-06Z | 1CB-18-06RNW | M18X1.5 | G3/8″X19 | 12 | 13.5 | 10 | 25 | 30.5 | 22 | 22 |

| 1CB-18-08Z | 1CB-18-08RNW | M18X1.5 | G1/2″X14 | 12 | 16 | 11 | 26 | 33 | 27 | 22 |

| 1CB-18-12Z | 1CB-18-12RNW | M18X1.5 | G3/4″X14 | 12 | 18.5 | 11 | 26 | 36.5 | 32 | 22 |

| 1CB-22-06Z | 1CB-22-06RNW | M22X1.5 | G3/8″X19 | 15 | 13.5 | 11 | 26 | 31.5 | 24 | 27 |

| 1CB-22-08Z | 1CB-22-08RNW | M22X1.5 | G1/2″X14 | 15 | 16 | 12 | 27 | 34 | 27 | 27 |

| 1CB-26-08Z | 1CB-26-08RNW | M26X1.5 | G1/2″X14 | 18 | 16 | 11.5 | 28 | 35 | 27 | 32 |

| 1CB-26-12Z | 1CB-26-12RNW | M26X1.5 | G3/4″X14 | 18 | 18.5 | 11.5 | 28 | 35.5 | 32 | 32 |

| 1CB-30-12Z | 1CB-30-12RNW | M30X2 | G3/4″X14 | 22 | 18.5 | 13.5 | 30 | 39.5 | 32 | 36 |

| 1CB-36-16Z | 1CB-36-16RNW | M36X2 | G1″X11 | 28 | 20.5 | 14.5 | 31 | 42.5 | 41 | 41 |

| 1CB-45-20Z | 1CB-45-20RNW | M45X2 | G1.1/4″X11 | 35 | 20.5 | 15.5 | 37 | 45.5 | 50 | 50 |

| 1CB-52-24Z | 1CB-52-24RNW | M52X2 | G1.1/2″X11 | 42 | 23 | 16 | 39 | 50 | 55 | 60 |

| 1DB-14-04Z | 1DB-14-04RNW | M14X1.5 | G1/4″X19 | 6 | 12 | 13 | 28 | 30 | 19 | 17 |

| 1DB-16-04Z | 1DB-16-04RNW | M16X1.5 | G1/4″X19 | 8 | 12 | 13 | 28 | 32 | 19 | 19 |

| 1DB-16-06Z | 1DB-16-06RNW | M16X1.5 | G3/8″X19 | 8 | 13.5 | 15 | 32 | 35.5 | 22 | 19 |

| 1DB-18-04Z | 1DB-18-04RNW | M18X1.5 | G1/4″X19 | 10 | 12 | 12.5 | 29 | 32 | 19 | 22 |

| 1DB-18-06Z | 1DB-18-06RNW | M18X1.5 | G3/8″X19 | 10 | 13.5 | 14.5 | 31 | 33.5 | 22 | 22 |

| 1DB-18-08Z | 1DB-18-08RNW | M18X1.5 | G1/2″X14 | 10 | 16 | 14.5 | 31 | 36 | 27 | 22 |

| 1DB-20-04Z | 1DB-20-04RNW | M20X1.5 | G1/4″X19 | 12 | 12 | 14.5 | 31 | 34 | 22 | 24 |

| 1DB-20-06Z | 1DB-20-06RNW | M20X1.5 | G3/8″X19 | 12 | 13.5 | 14.5 | 31 | 35.5 | 22 | 24 |

| 1DB-20-08Z | 1DB-20-08RNW | M20X1.5 | G1/2″X14 | 12 | 16 | 14.5 | 31 | 38 | 27 | 24 |

| 1DB-22-08Z | 1DB-22-08RNW | M22X1.5 | G1/2″X14 | 14 | 16 | 16 | 34 | 40 | 27 | 27 |

| 1DB-24-06Z | 1DB-24-06RNW | M24X1.5 | G3/8″X19 | 16 | 13.5 | 15.5 | 34 | 37.5 | 27 | 30 |

| 1DB-24-08Z | 1DB-24-08RNW | M24X1.5 | G1/2″X14 | 16 | 16 | 15.5 | 34 | 40 | 27 | 30 |

| 1DB-24-12Z | 1DB-24-12RNW | M24X1.5 | G3/4″X14 | 16 | 18.5 | 17.5 | 36 | 44.5 | 32 | 30 |

| 1DB-30-12Z | 1DB-30-12RNW | M30X2 | G3/4″X14 | 20 | 18.5 | 17.5 | 39 | 48.5 | 32 | 36 |

| 1DB-36-08Z | 1DB-36-08RNW | M36X2 | G1/2″X14 | 25 | 16 | 19 | 43 | 48 | 41 | 46 |

| 1DB-36-12Z | 1DB-36-12RNW | M36X2 | G3/4″X14 | 25 | 18.5 | 19 | 43 | 50.5 | 41 | 46 |

| 1DB-36-16Z | 1DB-36-16RNW | M36X2 | G1″X11 | 25 | 20.5 | 20 | 44 | 52.5 | 41 | 46 |

| 1DB-42-20Z | 1DB-42-20RNW | M42X2 | G1.1/4″X11 | 30 | 20.5 | 21.5 | 48 | 54.5 | 50 | 50 |

| 1DB-52-24Z | 1DB-52-24RNW | M52X2 | G1.1/2″X11 | 38 | 23 | 23 | 54 | 62 | 55 | 60 |

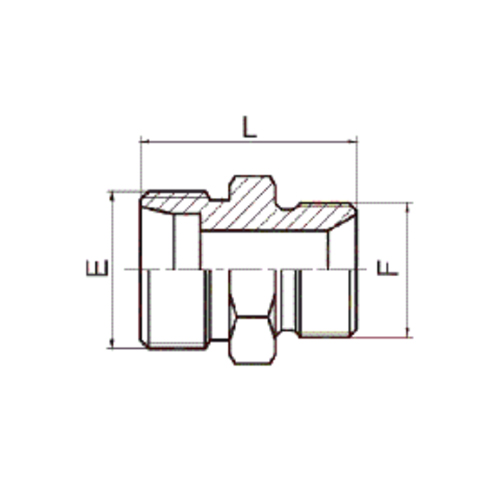

2. Dimensional Highlights

- Compact design: Average length 30-40% shorter than stackable adapters

- Precision-machined sealing surfaces:

- 24° cone angle (Metric side) per DIN 2353

- 60° taper (BSP side) per ISO 7-1

- Weight reduction: 15-20% lighter than equivalent two-piece adapter solutions

Performance Advantages

1. Superior Sealing Technology

- Dual-cone sealing system:

- 24° cone: Provides primary sealing for Metric connections

- 60° taper: Ensures leak-proof BSP threaded joints

- Eliminates common failure points:

- No O-rings to degrade over time

- No washers or gaskets required

2. Material & Construction

- Premium carbon steel (Grade 35CrMo) with:

- Hardened sealing surfaces (HRC 45-50)

- Corrosion-resistant plating (Zn-Ni alloy)

- Alternative materials available:

- Stainless steel (AISI 316L) for corrosive environments

- Brass for low-pressure pneumatic systems

3. Installation Benefits

- Single-component solution replaces multiple adapters

- Reduced potential leak paths: 50% fewer connections than traditional methods

- Tool-friendly design: Standard hex sizes for easy wrench access

Industry Applications

- Offshore/marine hydraulics: Where BSP and Metric systems interface

- Industrial machinery: Especially European-designed equipment in BSP regions

- Mobile equipment: Excavators, cranes with mixed-standard components

- Power generation: Hydraulic control systems in turbines

Quality Assurance

- 100% pressure testing at 1.5x rated working pressure

- Dimensional verification with CMM inspection

- Material certifications: EN 10204 3.1 mill certificates

- Traceability: Laser-marked part numbers for full lifecycle tracking

Why Choose This Metric Male 24° Cone / BSP 60° Cone Seal?

✅ Solves standardization conflicts in global hydraulic systems

✅ Higher reliability than O-ring dependent designs

✅ Space-saving compared to adapter stacks

✅ Reduced inventory – replaces multiple adapter combinations