Accurate Transfer

Professional

Hydraulic Hose Connector

Manufacturer

Zero leakage connection, ultra long durability, expert in industrial grade hydraulic adapters

Technology drives the future, innovation leads change - make R&D your core competitiveness!

From production to mass production, we define the closed loop of intelligent manufacturing

Tailored hydraulic connectors according to customer needs, providing after-sales support

Who we are

Production Hydraulic Joint Enterprise

Hebei Minglai Pipe Fitting Co., Ltd. is a professional company that produces standard and non-standard hydraulic hose connector, rubber products, etc. Our ultimate goal is to use the best materials, strictly test products according to our quality management system, and ensure customer satisfaction. Minglai Pipe Fitting Co., Ltd. is a professional company that produces standard and non-standard hydraulic joints, rubber products, etc. Our ultimate goal is to use the best materials, strictly test products according to our quality management system, and ensure customer satisfaction.

reliable quality

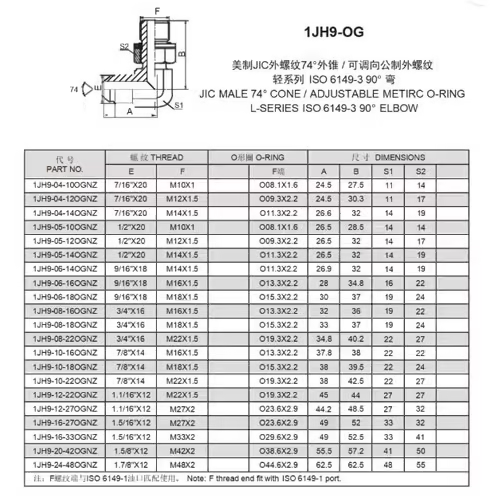

Explore Our Products

reliable quality

Hot-Sale Product

Support customization

Provide You With Customized Solutions

- A professional design team with independent development capabilities

- A comprehensive manufacturing and testing system ensures product quality

- Customization is supported, flexibly addressing diverse needs

- Full lifecycle technical support and rapid service response

- Insisting on innovation and quality to build a brand trusted by customers

We are dedicated to providing highly specialized custom stainless steel hydraulic components. Leveraging our strong engineering capabilities, precision manufacturing processes, and rigorous quality inspection systems, we fully meet the personalized hydraulic system component needs of clients across various industries. Our services encompass not only product design, manufacturing, and performance testing, but also full-lifecycle technical support and after-sales service, helping clients improve system efficiency, reduce maintenance costs, and shorten project cycles.

Why Choose Us

We Help You Solve Your Problems

We have 6 major advantages that enable us to better meet your needs.

Certificates

The product has passed IP68 waterproof, CE, UL, ROHS and other international certifications

Craftsmanship

Advanced processes such as precision forging and laser welding ensure product accuracy and durability

Process

Professional and complete workflow, direct supply from source manufacturers

Quality Control

Strictly follow GB/T, ASME, DIN and other standards in production

R&D Capability

Support customization to meet the needs of customers in various industries

Our Clients

Cooperate with well-known enterprises, including OEM/ODM services, customization, etc.

Customer Feedback On Us

Persist in using the best materials to make customers trust us

Common Questions

Most Popular Questions

Replace the hydraulic joint with a new one and thoroughly clean the welding slag and oil stains inside the pipe with kerosene or anhydrous ethanol before installation to ensure that the sealing surface is free of impurities.

Surface strengthening treatment:

Plated with hard chromium (thickness ≥ 0.02mm) or coated with molybdenum disulfide lubricant (suitable for working conditions of -20~200 ℃) at the thread;

The key parts are made of stainless steel material (such as 316L), and there is no corrosion after salt spray testing for ≥ 720 hours.

Suggestions for rust prevention management:

Install a moisture-proof silicone bag during storage, and apply rust proof oil to the contact surface;

Regularly check the cleanliness of the threads (by blowing with high-pressure gas to prevent impurities from accumulating).

Emergency response plan:

Rusted threads can be softened with WD-40 penetrant and cleaned with a nylon brush; Severe corrosion requires cutting off the damaged section and re tapping.

Accurate selection guide:

Working pressure ≤ 80% of the nominal pressure of the joint (e.g. 50MPa grade joint is selected for 35MPa system);

An additional 30% margin is added for impact conditions, and the pressure in high-temperature environments is converted based on the temperature coefficient (reduced by 20% for every 100 ℃).

Strengthen testing verification:

Provide a third-party pressure pulse test report (such as no leakage after 100000 0.5Hz square wave tests);

Add safety relief valves to critical areas (set value<10% of maximum system pressure).

Structural optimization suggestions:

Adopting a double-layer sealing structure (main seal+buffer ring) to absorb pressure fluctuations;

Thickened pipe wall material (such as high-pressure hose joint SC5S outer diameter ≥ 25mm).

Standardized control measures:

Establish a thread identification system (laser print "NPT-1/2-28UNF" on the joint);

Provide a size comparison table (including ISO/ANSI/DIN standard conversion parameters).

Precision detection equipment:

Use an electronic thread gauge (accuracy ± 0.01mm) to detect the tooth profile angle (60 ° or 55 °);

The ovality of the tube body is ≤ 0.05mm (it is recommended to submit samples for retesting before procurement).

Professional installation guidance:

Adopting the torque step method (initial torque 50% → compound torque 100% → final torque 120%);

It is recommended to use a hydraulic torque wrench (with an accuracy of ± 3%) in conjunction with a fixed torque socket.

Our Latest Articles

Get To Know The Latest News About Our Products

5 Vital Bulk Hydraulic Hose Tips for Longevity

Extend your Bulk Hydraulic Hose life with 5 proven tips for safety, durability, and peak performance in industrial applications.

6 Hydraulic Crimp Fitting Problems: What You Need to Know

Learn how to identify Hydraulic Crimp Fitting issues, prevent leaks, and ensure safe, high-pressure hydraulic system performance.

3/8 Hydraulic Fittings Buying Guide: What You Need to Know Before Purchasing

Learn how to choose 3/8 Hydraulic Fittings with this practical buying guide covering specs, materials, pressure ratings, and common mistakes.

Get in touch

Don't Hesitate To Contact Us For More Information

Send Us A Message

We will contact you after receiving it