Description

Metric Male 24° Cone / Adjustable Metric Male O-Ring Branch Tee – DIN Standard Hydraulic Connector

Product Overview

The Metric Male 24° Cone / Adjustable Metric Male O-Ring Branch Tee is a precision-engineered hydraulic fitting designed for high-pressure fluid systems requiring secure, leak-free connections. Unlike standard branch tees, this model features a fully adjustable Metric Male stud end, allowing for precise alignment and installation flexibility.

Compatible with Metric threads (M12×1.5 to M42×2), it is ideal for industrial hydraulics, mobile machinery, and heavy-duty fluid transfer systems where DIN-standard reliability is essential.

Key Features & Competitive Advantages

1. Adjustable Metric Male Stud End for Easy Installation

- Unlike fixed-thread tees, this model allows 360° adjustabilityfor optimal alignment with piping layouts.

- Eliminates the need for additional adapters, reducing installation time and potential leak points.

2. Dual Sealing: 24° Cone + O-Ring for Maximum Leak Resistance

- 24° Cone Seal (ISO 8434-1 / DIN 2353)– Ensures metal-to-metal sealing under extreme pressure.

- Integrated O-Ring (NBR, FKM options)– Provides secondary sealing against vibration and thermal cycling.

3. High-Strength Materials & Corrosion Protection

- Material Options:

- Carbon Steel (45# / 55#)– Standard version, zinc-plated for corrosion resistance.

- Stainless Steel (AISI 304 / 316)– For marine, chemical, or food-grade applications.

- Surface Finishes:Zinc plating (standard), Zn-Ni plating (enhanced corrosion resistance).

4. Strict DIN Compliance & Quality Assurance

- Manufactured under ISO 9001quality systems.

- Tested for:

- Pressure resistance (up to 40 MPa / 5800 psi)

- Torque retention

- Leak-proof performance

5. Customizable Options for Specialized Applications

- Non-standard thread sizes(upon request).

- Alternative O-Ring materials(Viton, EPDM, HNBR).

- Special coatings(Black oxide, Dacromet).

Technical Specifications (Selected Models)

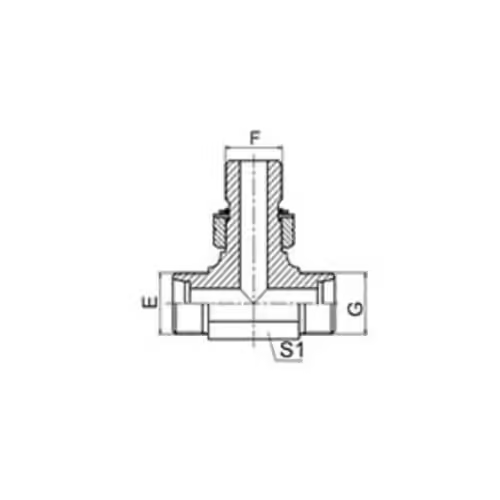

| PART NO. | THREAD | D1,D2 TUBE O.D. | O RING | DIMENSIONS | |||||||

| BODY | ASSEMBLY | E,G | F | l1,l2 | L1,L2 | L3 | S1 | S2,S4 | S3 | ||

| ACHC-12-10-12OGNZ | ACHC-121012OGNRNW | M12X1.5 | M10X1 | 6 | O08.1X1.6 | 13 | 28 | 26.5 | 11 | 14 | 14 |

| ACHC-14-12-14OGNZ | ACHC-141214OGNRNW | M14X1.5 | M12X1.5 | 8 | O09.3X2.2 | 15.5 | 30.5 | 32 | 14 | 17 | 17 |

| ACHC-16-14-16OGNZ | ACHC-161416OGNRNW | M16X1.5 | M14X1.5 | 10 | O11.3X2.2 | 17.5 | 32.5 | 34 | 16 | 19 | 19 |

| ACHC-18-16-18OGNZ | ACHC-181618OGNRNW | M18X1.5 | M16X1.5 | 12 | O13.3X2.2 | 19 | 34 | 36 | 19 | 22 | 22 |

| ACHC-22-18-22OGNZ | ACHC-221822OGNRNW | M22X1.5 | M18X1.5 | 15 | O15.3X2.2 | 22 | 37 | 39.5 | 22 | 27 | 24 |

| ACHC-26-22-26OGNZ | ACHC-262226OGNRNW | M26X1.5 | M22X1.5 | 18 | O19.3X2.2 | 25.5 | 42 | 43.5 | 27 | 32 | 27 |

| ACHC-30-27-30OGNZ | ACHC-302730OGNRNW | M30X2 | M27X2 | 22 | O23.6X2.9 | 29.3 | 45.8 | 50 | 30 | 36 | 32 |

| ACHC-36-33-36OGNZ | ACHC-363336OGNRNW | M36X2 | M33X2 | 28 | O29.6X2.9 | 33.3 | 49.8 | 54 | 36 | 41 | 41 |

| ADHD-14-12-14OGNZ | ADHD-141214OGNRNW | M14X1.5 | M12X1.5 | 6 | O09.3X2.2 | 17.5 | 32.5 | 32 | 14 | 17 | 17 |

| ADHD-16-14-16OGNZ | ADHD-161416OGNRNW | M16X1.5 | M14X1.5 | 8 | O11.3X2.2 | 18.7 | 33.7 | 34 | 16 | 19 | 19 |

| ADHD-18-16-18OGNZ | ADHD-181618OGNRNW | M18X1.5 | M16X1.5 | 10 | O13.3X2.2 | 19.5 | 36 | 36 | 19 | 22 | 22 |

| ADHD-20-18-20OGNZ | ADHD-201820OGNRNW | M20X1.5 | M18X1.5 | 12 | O15.3X2.2 | 19.5 | 36 | 37 | 19 | 24 | 24 |

| ADHD-24-22-24OGNZ | ADHD-242224OGNRNW | M24X1.5 | M22X1.5 | 16 | O19.3X2.2 | 24 | 42 | 37.5 | 24 | 30 | 27 |

| ADHD-30-27-30OGNZ | ADHD-302730OGNRNW | M30X2 | M27X2 | 20 | O23.6X2.9 | 28.3 | 49.8 | 50 | 30 | 36 | 32 |

| ADHD-36-33-36OGNZ | ADHD-363336OGNRNW | M36X2 | M33X2 | 25 | O29.6X2.9 | 32.8 | 56.8 | 54 | 36 | 46 | 41 |

| ADHD-42-42-42OGNZ | ADHD-424242OGNRNW | M42X2 | M42X2 | 30 | O38.6X2.9 | 36.2 | 62.7 | 57.2 | 41 | 50 | 50 |

| Note: F thread end fit with ISO 6149-1 port. | |||||||||||

Applications

✔ Mobile Hydraulics – Excavators, loaders, cranes.

✔ Industrial Machinery – Hydraulic presses, CNC systems.

✔ Agricultural Equipment – Tractors, harvesters, irrigation systems.

✔ Energy & Oilfield Systems – Hydraulic power units, drilling equipment.

Why Choose This Adjustable Branch Tee?

✅ Superior Adjustability – No need for extra swivel fittings, saving cost and space.

✅ DIN/ISO Certified – Meets ISO 8434-1 & DIN 2353 for global compliance.

✅ Leak-Proof Design – Dual-seal system outperforms standard O-ring-only fittings.

✅ Wide Material Selection – Carbon steel, stainless steel, and custom coatings available.