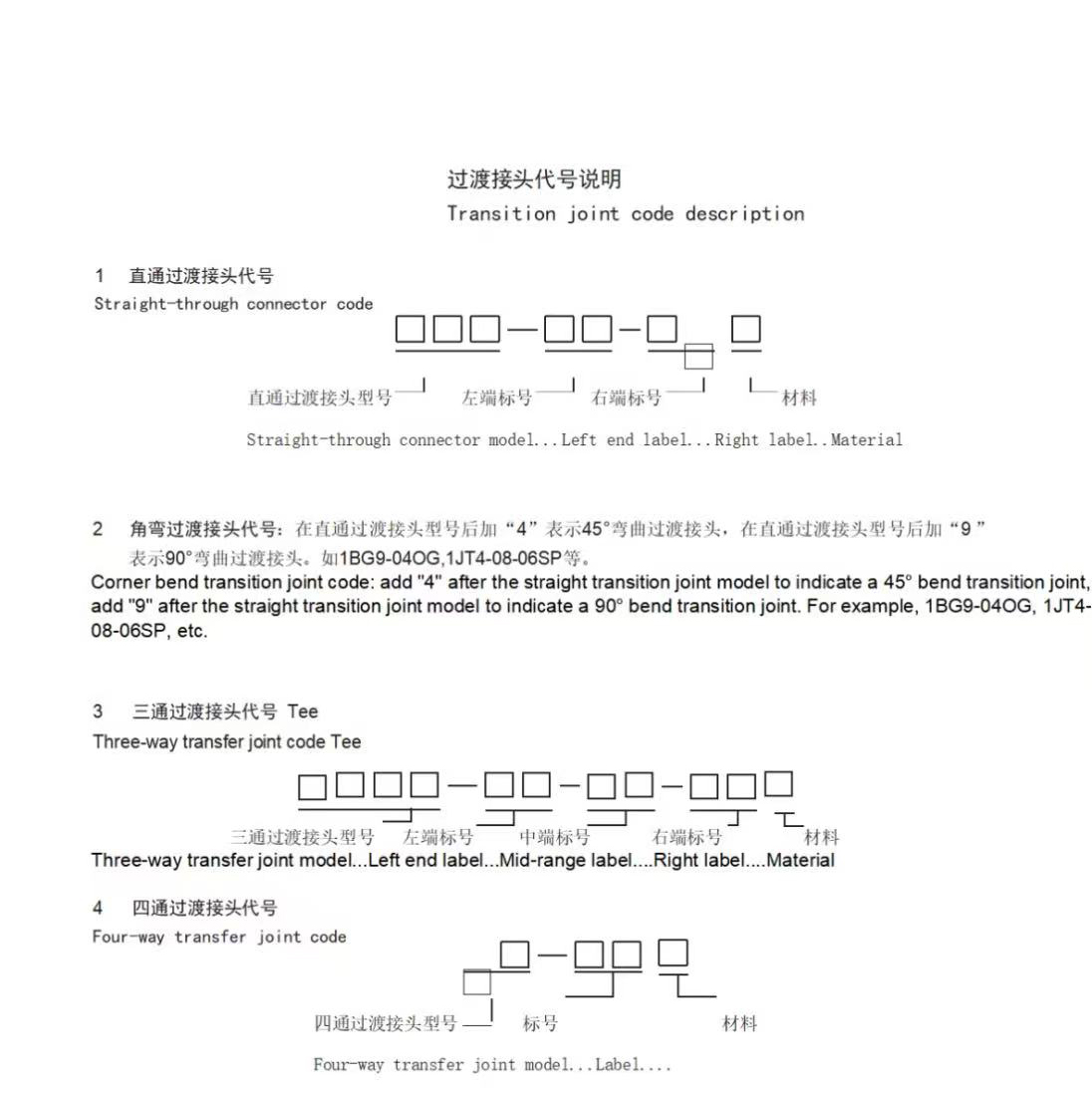

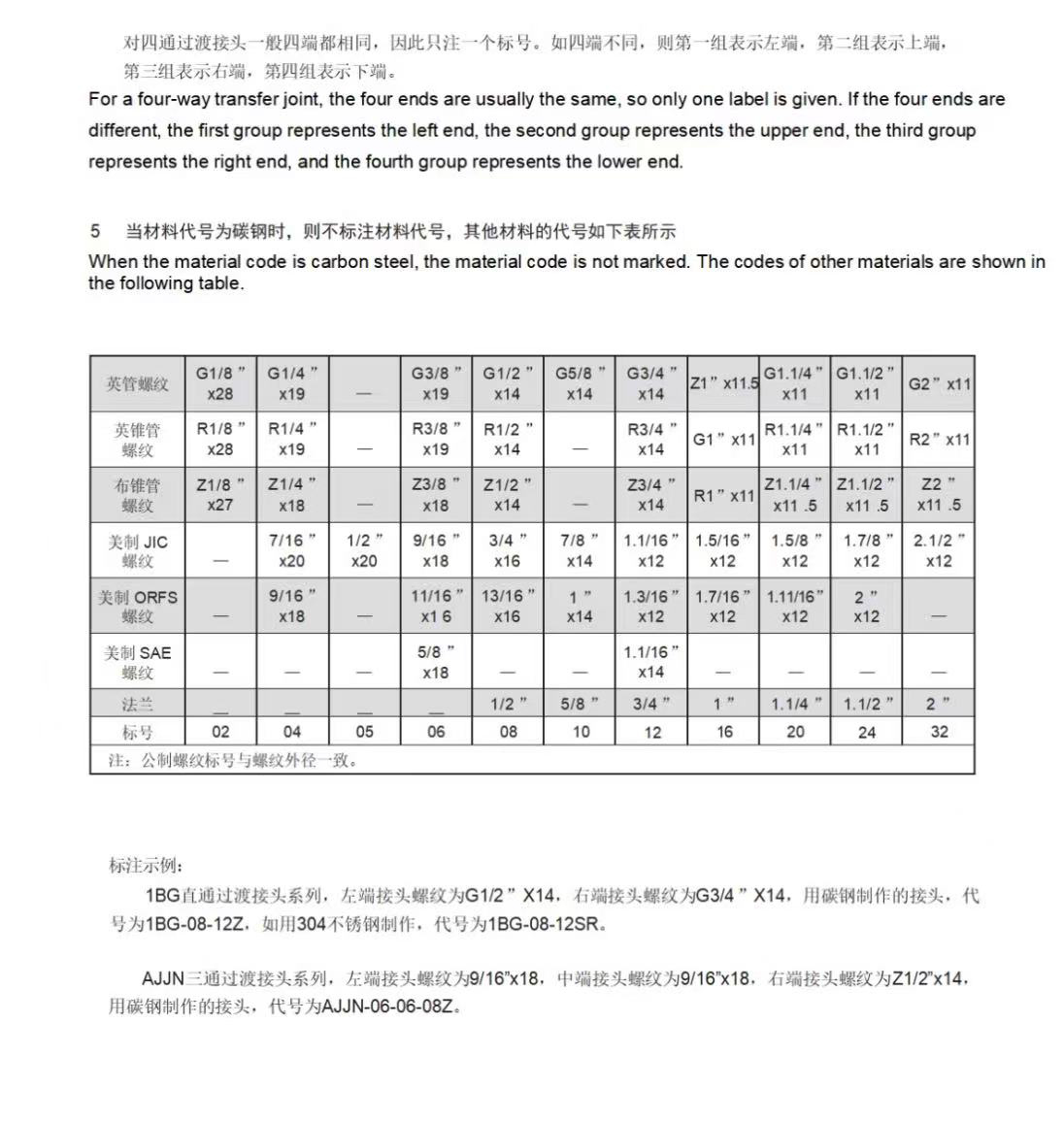

Description

Metric Male 24° Cone / Metric Female 24° Cone Run Tee – High-Performance Hydraulic Fitting

Overview of the Metric Male/Female 24° Cone Run Tee

The Metric Male 24° Cone / Metric Female 24° Cone Run Tee is a critical hydraulic pipe fitting designed to provide a secure and leak-tight connection in high-pressure fluid systems. This run tee connector is specifically engineered to adapt between various metric threads ranging from M12×1.5 to M52×2, while supporting a wide range of tube outer diameters. It is ideal for applications requiring reliable performance in harsh environments and is widely used in the hydraulic systems of industrial machinery, construction equipment, and automotive systems.

Key Features

- Dual-thread design: Metric male and female 24° cone connections

- Thread range: M12×1.5 up to M52×2

- Tube O.D. compatibility: 6mm to 42mm

- Leak-proof design: O-ring sealing technology ensures tight connections

- Durable materials: High-quality carbon steel or stainless steel construction

- Compliant with DIN standard specifications

- Customizable options for special applications

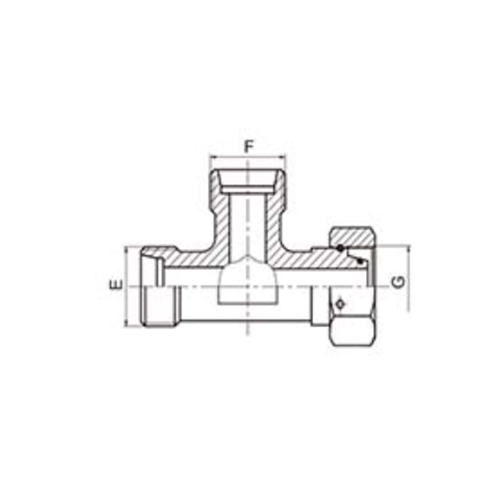

Technical Specifications of the Run Tee

This section outlines the detailed dimensional and mechanical data of the Metric Male 24° Cone / Metric Female 24° Cone Run Tee, including part numbers, thread sizes, tube compatibility, and key dimensions. These specifications ensure accurate integration into hydraulic systems and facilitate proper installation and maintenance.

Dimensional Chart

| PART NO. | THREAD | TUBE O.D. | O-RING | DIMENSIONS | ||||||||

| BODY | ASSEMBLY | E,F | G | D1,D2 | D3 | l1,l2 | L1,L2 | L3 | S1 | S2,S3 | S4 | |

| CC-12Z | CC-12RNW | M12X1.5 | M12X1.5 | 6 | 6 | O04.5×1.5 | 12 | 27 | 26 | 12 | 14 | 14 |

| CC-14Z | CC-14RNW | M14X1.5 | M14X1.5 | 8 | 8 | O06.5×1.5 | 14 | 29 | 27.5 | 12 | 17 | 17 |

| CC-16Z | CC-16RNW | M16X1.5 | M16X1.5 | 10 | 10 | O08.0x1.5 | 15 | 30 | 29 | 14 | 19 | 19 |

| CC-18Z | CC-18RNW | M18X1.5 | M18X1.5 | 12 | 12 | O10.0x1.5 | 17 | 32 | 29.5 | 17 | 22 | 22 |

| CC-22Z | CC-22RNW | M22X1.5 | M22X1.5 | 15 | 15 | O12.0x2.0 | 21 | 36 | 32.5 | 19 | 27 | 27 |

| CC-26Z | CC-26RNW | M26X1.5 | M26X1.5 | 18 | 18 | O15.0x2.0 | 23.5 | 40 | 35.5 | 24 | 32 | 32 |

| CC-30Z | CC-30RNW | M30X2 | M30X2 | 22 | 22 | O20.0x2.0 | 27.5 | 44 | 38.5 | 27 | 36 | 36 |

| CC-36Z | CC-36RNW | M36X2 | M36X2 | 28 | 28 | O26.0x2.0 | 30.5 | 47 | 41.5 | 36 | 41 | 41 |

| CC-45Z | CC-45RNW | M45X2 | M45X2 | 35 | 35 | O32.0x2.5 | 34.5 | 56 | 51 | 41 | 50 | 50 |

| CC-52Z | CC-52RNW | M52X2 | M52X2 | 42 | 42 | O38.0x2.5 | 40 | 63 | 56 | 50 | 60 | 60 |

| CD-14Z | CD-14RNW | M14X1.5 | M14X1.5 | 6 | 6 | O04.5×1.5 | 16 | 31 | 27 | 12 | 17 | 17 |

| CD-16Z | CD-16RNW | M16X1.5 | M16X1.5 | 8 | 8 | O06.5×1.5 | 17 | 32 | 27.5 | 14 | 19 | 19 |

| CD-18Z | CD-18RNW | M18X1.5 | M18X1.5 | 10 | 10 | O08.0x1.5 | 17.5 | 34 | 30 | 17 | 22 | 22 |

| CD-20Z | CD-20RNW | M20X1.5 | M20X1.5 | 12 | 12 | O10.0x1.5 | 21.5 | 38 | 31 | 17 | 24 | 24 |

| CD-22Z | CD-22RNW | M22X1.5 | M22X1.5 | 14 | 14 | O11.0x2.0 | 22 | 40 | 35 | 19 | 27 | 27 |

| CD-24Z | CD-24RNW | M24X1.5 | M24X1.5 | 16 | 16 | O13.0x2.0 | 24.5 | 43 | 36.5 | 24 | 30 | 30 |

| CD-30Z | CD-30RNW | M30X2 | M30X2 | 20 | 20 | O16.3×2.4 | 26.5 | 48 | 44.5 | 27 | 36 | 36 |

| CD-36Z | CD-36RNW | M36X2 | M36X2 | 25 | 25 | O20.3×2.4 | 30 | 54 | 50 | 36 | 46 | 46 |

| CD-42Z | CD-42RNW | M42X2 | M42X2 | 30 | 30 | O25.3×2.4 | 35.5 | 62 | 55 | 41 | 50 | 50 |

| CD-52Z | CD-52RNW | M52X2 | M52X2 | 38 | 38 | O33.3×2.4 | 41 | 72 | 63 | 50 | 60 | 60 |

Applications of the 24° Cone Run Tee

Where is This Tee Fitting Commonly Used?

The Metric Male 24° Cone / Metric Female 24° Cone Run Tee is widely applied in the following fields due to its high-pressure resistance, leak-proof design, and compatibility with various metric standards:

- Industrial Hydraulics: Hydraulic presses, metalworking machines, and automation equipment

- Construction Machinery: Excavators, bulldozers, cranes, and loaders

- Agricultural Equipment: Tractors, harvesters, and irrigation systems

- Automotive Systems: Power steering systems, braking systems, and transmission cooling lines

- Marine and Offshore Equipment: Hydraulic control systems in ships and offshore platforms

Its versatility and durability make it a preferred choice for engineers and technicians working on complex fluid power systems.

Why Choose Our Metric Cone Run Tee Fittings?

Quality, Durability, and Customization Combined

At our company, we adhere to the highest standards in the design and manufacturing of hydraulic fittings. Our Metric Male 24° Cone / Metric Female 24° Cone Run Tee is built to last and perform under the most demanding conditions.

1. Strict Quality Control & Certifications

All our products undergo rigorous quality inspections and are certified to meet ISO 9001, DIN, and other international standards. Each batch is tested for pressure resistance, leakage, and material integrity to ensure consistent performance.

2. High-Quality Materials & Durability

Manufactured from high-grade carbon steel or stainless steel, our fittings offer excellent corrosion resistance and mechanical strength. They are often surface-treated with zinc or nickel plating to enhance longevity and environmental resistance.

3. Customizable Solutions

We understand that not all hydraulic systems are the same. Our team provides OEM/ODM services, including custom threading, size adjustments, and packaging options, to meet your exact technical and logistical requirements.

4. Comprehensive After-Sales Support

From technical consultations to product troubleshooting and logistical support, our customer service team is available to assist you at every stage. We also offer sample orders, bulk discounts, and fast global shipping.